Using of CPE HG 100

for 3D printing of adapters for testing the pumps

This case study is focused on one of the most popular Fillamentum materials, CPE HG100. It is modified PETG, developed for more technical prints. With the CPE HG100 you can look forward to easy 3D printing and prints that are nice even in details. For company OLKA Struna, work is fun and a conversation about 3D printing was held also in a cheerful spirit. Find more details in the interview below.

Why did you use technology of 3D printing? What was the main reason?

The main reason is a specific design of the final product that is not commercially available on the market.

Was this a solution to any problem?

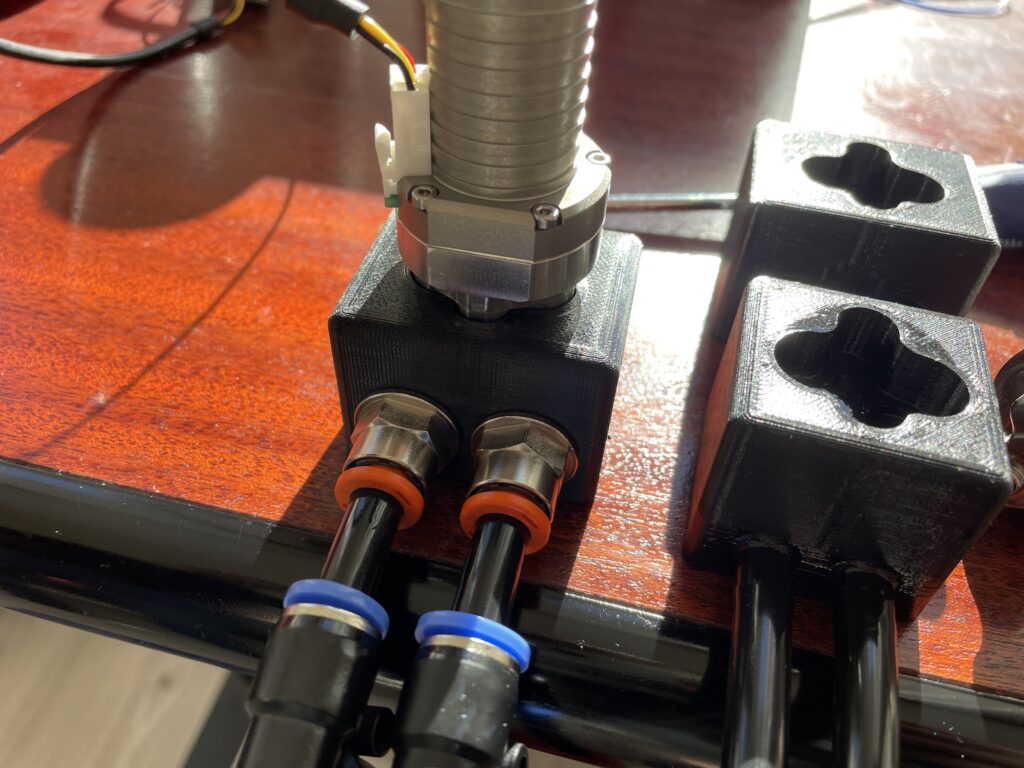

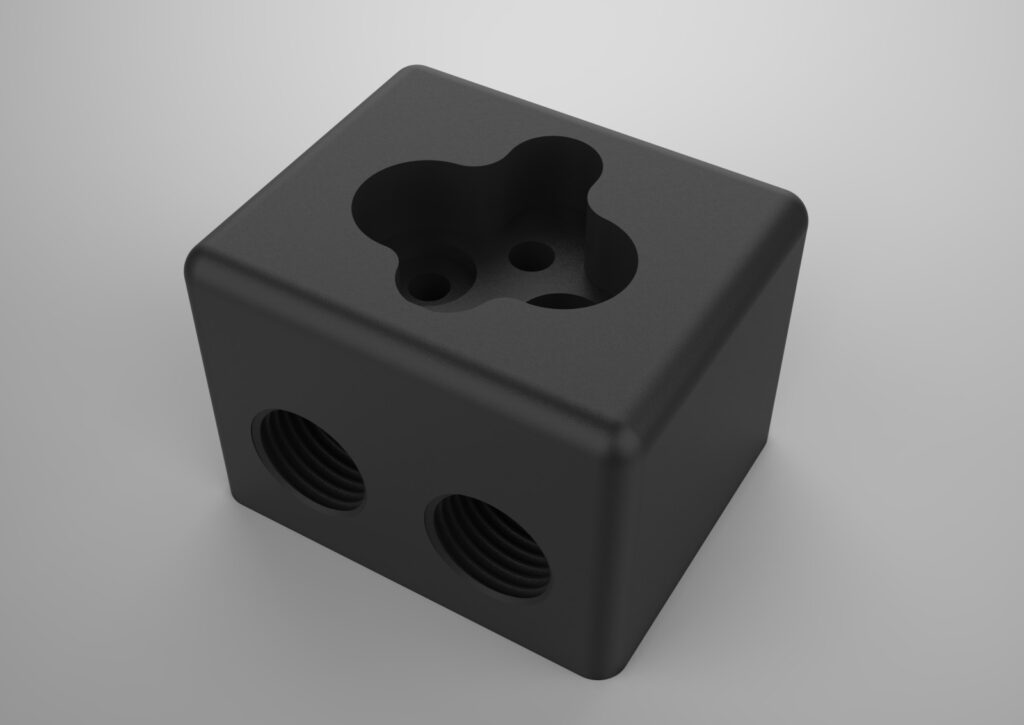

Yes. We needed to make an adapter for testing pumps for high-viscosity oils. The part is used as an adapter for testing the pumps.

Did you make any time or cost savings?

Such prototype made from aluminum is financially demanding to make, because when it is taken into a consideration the work of the CAM programmer creating a CNC program, then the time required to set up the machine, the waiting time to create a product, 3D printing wins with no doubts. In addition, we are huge fans of 3D printing, programming, designing the composition and the construction of our own products, we often do not care about time or money. Rather, we want the final product to meet our difficult requirements and fit into our ecosystem, and just finding such a product on the market is a very difficult task.

How is the printing with materials from Fillamentum?

The used material was CPE HG100. Why did we choose this material? As we work with oils that are quite aggressive and used in the robotic industry, the choice was clear and fell on CPE HG100. Simple 3D printing, strength, flexibility, colorfastness, and especially the chemical resistance of the CPE material makes it an ideal choice. And how was the 3D printing? Since the printing pads with a PEI surface are used when printing, the printing of CPE material is undemanding. The adhesion of the material is easy-going – there is no peeling off and after the pad cools down, the printout is easily removable from the surface.

What do you enjoy most about Fillamentum materials, why did you choose Fillamentum filaments?

In our opinion, Fillamentum is one level higher than other companies. Fillamentum is always our first choice when we embark on a project where 3D printing is needed. Why? The filament that this company offers exceeds other brands in added value. Whether it is the quality of the filament, the packaging, or the accuracy of the spool winding (this is an important factor against tangling of the filament on the spool).