Company Fremach is a supplier of complex plastic components in automotive. With more than 1,500 employees worldwide, Fremach supplies business partners such as Audi, BMW, Mercedes-Benz, VW, Volvo, and Continental.

“The benefits of 3D printing are obvious and are increasingly important to our business. Especially in the automotive, there is necessary to be flexible to customer requirements,” says Miroslava Pribylova, a process engineer in Fremach.

PROTOTYPING WITH CPE HG100

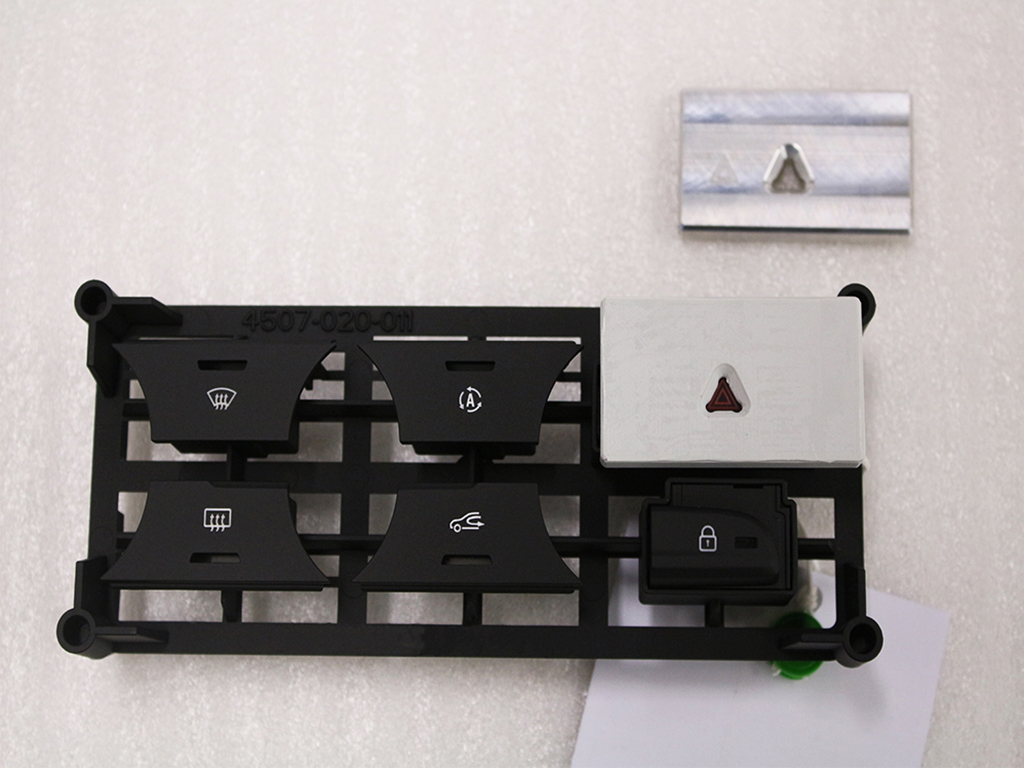

For company Fremach, it is important to test the functionality of coating and laser preparations before mass production. These coating preparations are used to cover some parts of a product that cannot be painted (for example functional parts or parts that are illuminated after the symbols are lasered). The printed object must hold well and not move. Thanks to additive technology the designers can reveal shortcomings before the final mold for mass production. For this purpose, CPE HG100 by Fillamentum is used because the preparations must sometimes handle high temperatures (around 80 °C). CPE HG100 is known for high-temperature resistance and low deformation of the printed objects.

The huge advantage of this process is cost and time-saving. The cost of mold reparations is enormous, time-consuming and often combined with the creation of security stocks. Another of many advantages is that the final mold can be designed and tuned according to customer requirements basically immediately. Due to easy and fast adjustments, new samples for customers can be made without any delay.

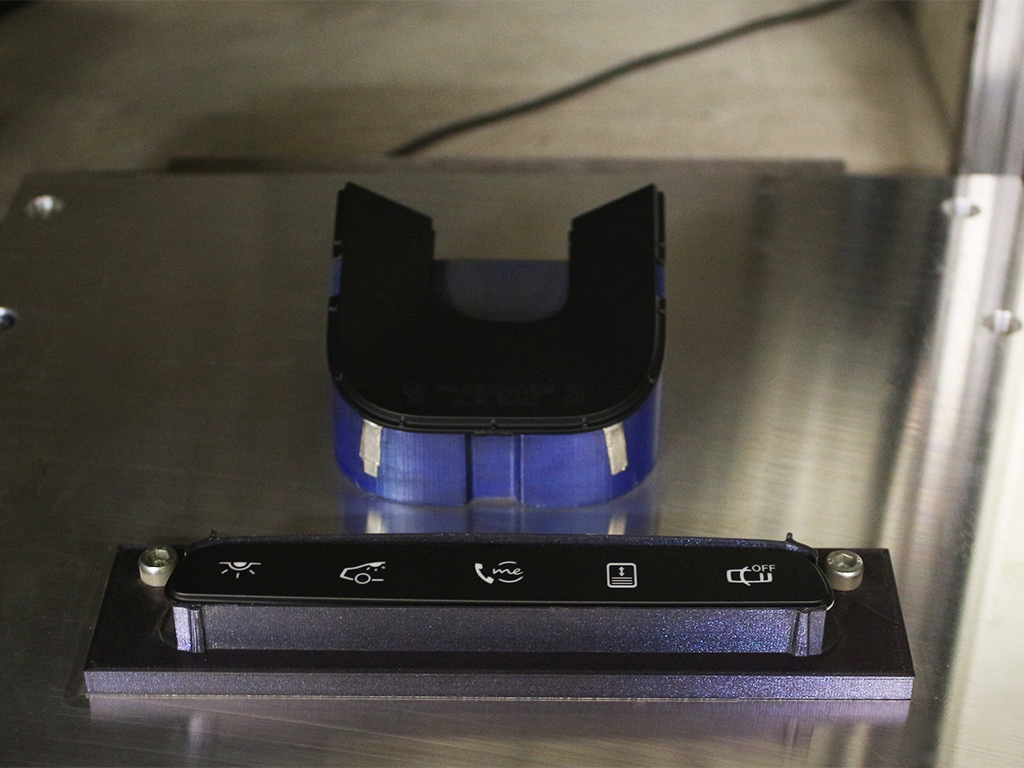

METAL REPLACEMENT WITH USAGE OF CPE HG100 AND PLA EXTRAFILL

This is the printing of a metal fixture for fastening parts intended for lasering of symbols (mostly buttons for using a function such as air conditioning, navigation, radio, etc.) The position of the symbols must be accurate within ± 0.1 – 0.25 mm.

And again, in this case, 3D printing saves time and, above all, the huge financial costs in production. The estimated price of production of the metal jig for lasering is about 160Eur, while the printed jig requires the weight of 100g of filament, which costs about 3 Eur. Savings account for an incredible 98% of costs.

In addition, the printing of the laser fixture for intending the parts is possible within one day. If the laser preparation needs to be re-designed, the modification of the printed objects can be done immediately.

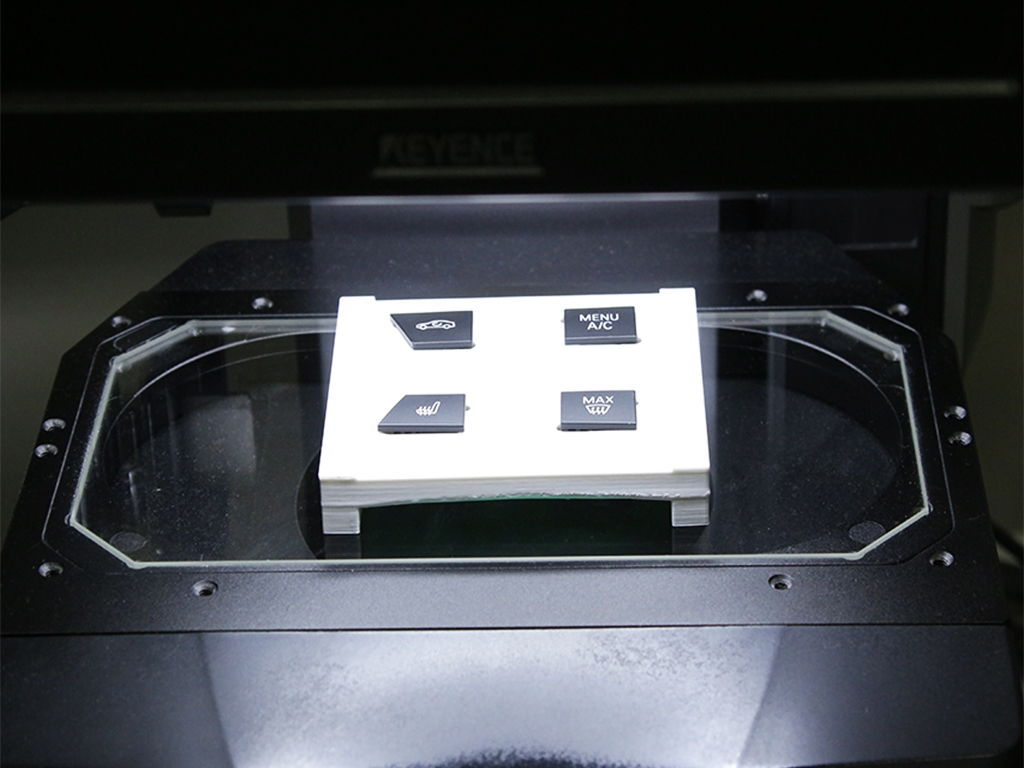

MEASURING PREPARATIONS AND USAGE OF CPE HG100

The third case of implementation of 3D printing in Fremach is about fastening the production of measuring jigs. These jigs are used for the correct placement of parts when measuring mostly lasered symbols.

Each part must be placed as shown in the drawing. It is also important to think of the holes in the measuring tool, which allow sufficient back-lighting of the symbols.

The estimated price of such a measuring device is about 160Eur. For a 3D printed measuring device is used 50 g of filament, which costs about 1.5Eur.

| Cookie | Description |

|---|---|

| _dc_gtm_UA-189275971-1 | The functionality is to store number of service requests. |

| _ga | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assigns a randomly generated number to identify unique visitors. |

| _ga_L703XWXLV0 | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_189275971_1 | Set by Google to distinguish users. |

| _gid | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |