Fillamentum is a producer of top-quality filaments for industrial applications. No wonder that we have applied our own 3D printed components into production.

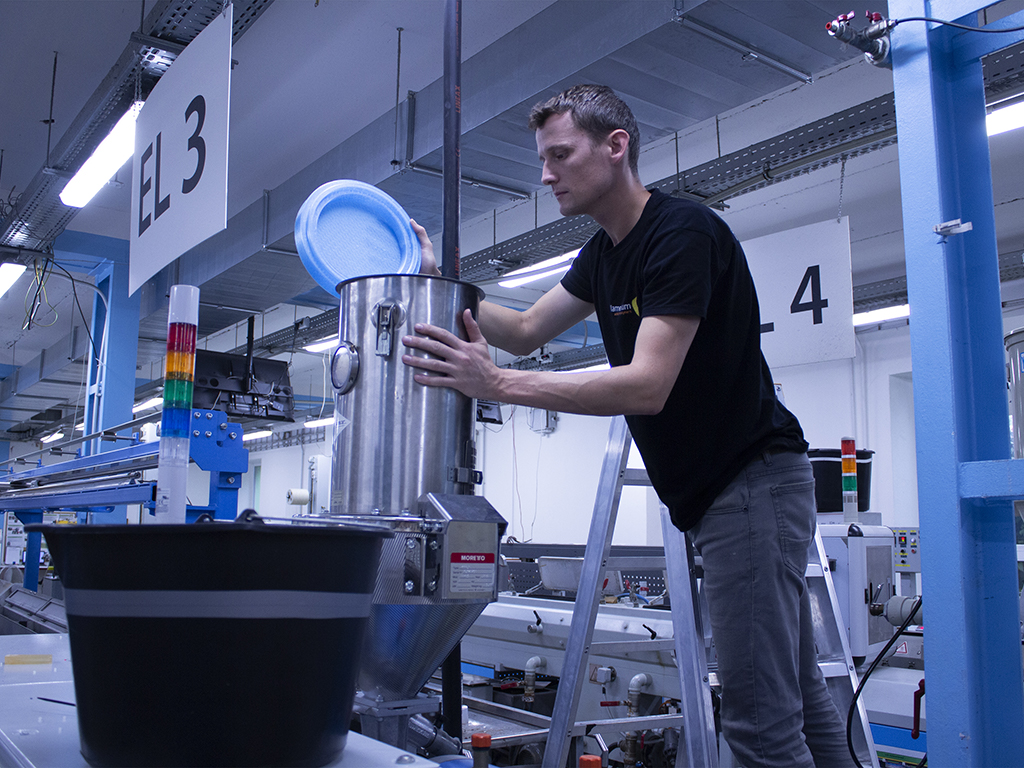

Hopper lid

Before a material for filaments is processed it needs to be perfectly dry. The material is dried in the hopper with the metal lid and during drying the temperature can reach up to 70 °C. The original heavy metal lid was replaced with lighter PLA. But this material cannot withstand high temperatures and the lid was twisted by the heat. The new version was printed in PETG that resists high temperatures. At the same time, PETG has a perfect tightness due to minimal shrinkage and excellent dimensional stability.

Cups for collecting hot material

Material is usually mixed with colored masterbatch. When mixing the material one can manipulate with granulate that reaches high temperatures, sometimes up to 75 °C. Mixing takes place in a special industrial box, in which the hot material is poured. For this application, PETG cups are used. PETG is used because of its long-term dimensional stability in high temperatures.

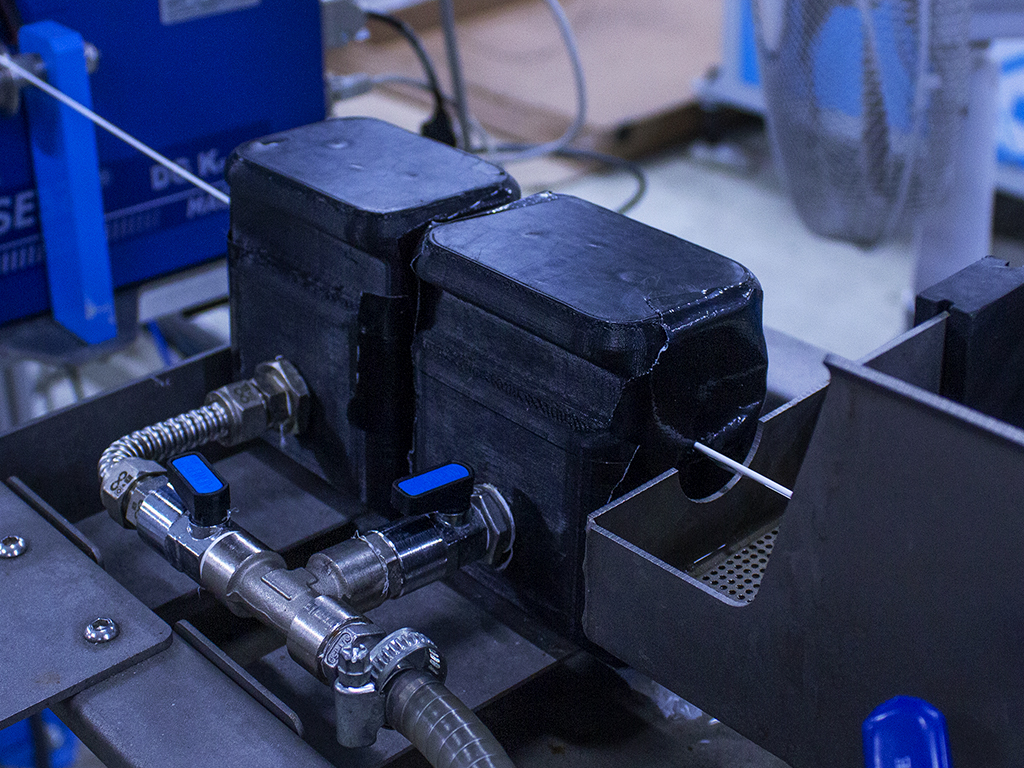

Boxes for moisture extraction

PETG material is, thanks to its dimensional stability, suitable also for applications where there is necessary high tightness. Like the two-parts box which purpose is to get rid of excess water on the surface of the extruded filament. Leaks were causing problems and the extruded filament was not dry enough. PETG is more resistant to water than CPE HG100 that was used for the box originally.

| Cookie | Description |

|---|---|

| _dc_gtm_UA-189275971-1 | The functionality is to store number of service requests. |

| _ga | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assigns a randomly generated number to identify unique visitors. |

| _ga_L703XWXLV0 | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_189275971_1 | Set by Google to distinguish users. |

| _gid | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |