“Turning waste into wonders with Fishy Filaments”

Fishy Filaments

This type of sustainable filament is 100% recycled nylon PA6 that comes from used fishing nets, which are a major environmental burden.

This sustainable nylon PA6 currently contains

2 types. These are:

- Porthcurno filaments are mainly used

in homewares, wearables, fashion and other

aesthetic products due to their attractive

translucent blue-green colour. - OrCA® filaments are part of a family of materials

aimed at technical applications that may include

carbon allotropes such as graphene or carbon fibers.

The Fishy Filaments Story

In 2016, Ian Falconer recognized the dire need to address the environmental consequences of waste generated by nylon monofilament fishing nets. To tackle this issue head-on, he founded Fishy Filaments, a company with a mission to transform these end-of-life nets into a valuable resource through an innovative recycling process that requires only freshwater and energy.

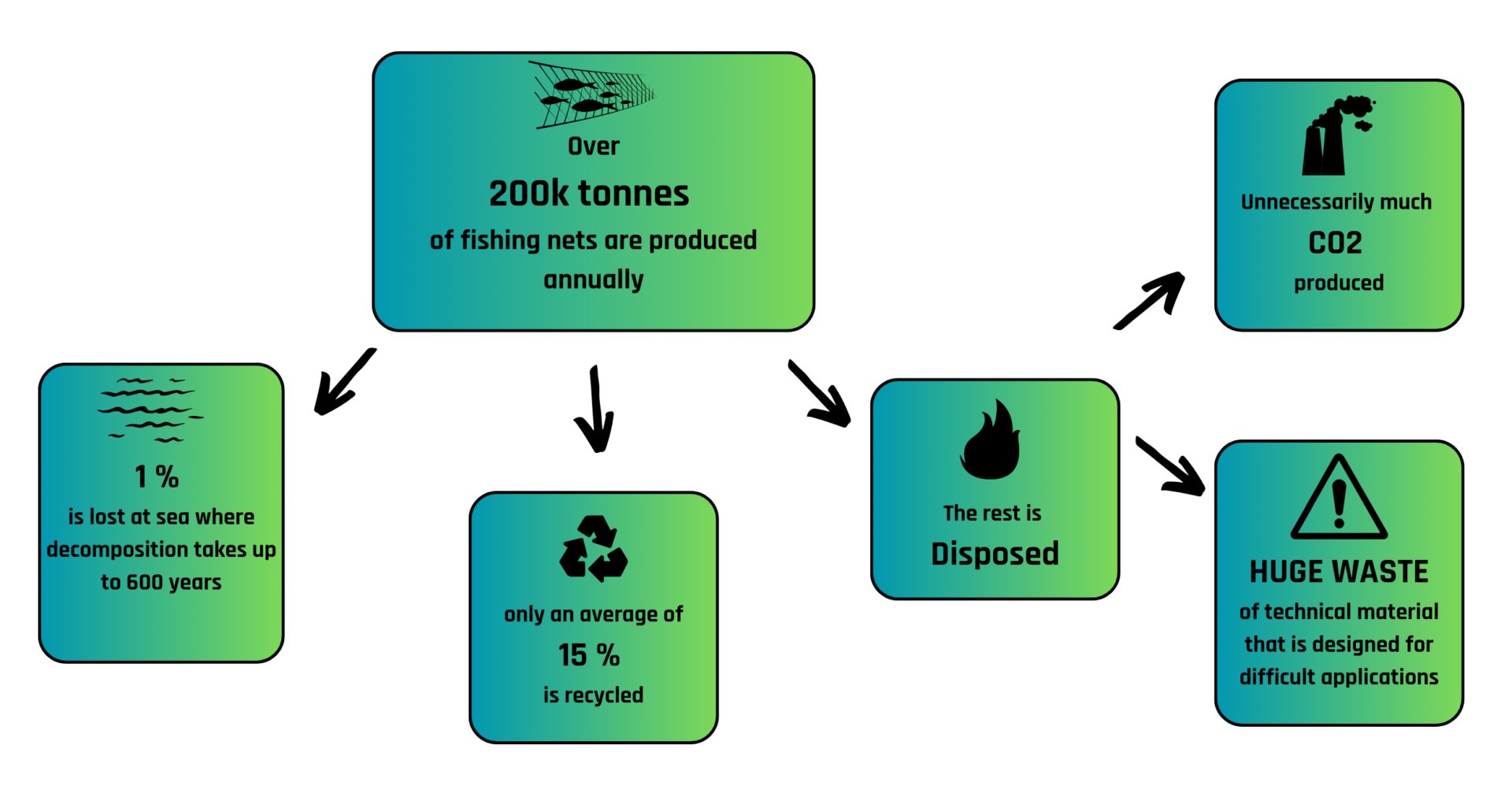

“The plastics industry knows that it sells somewhere around 200,000 tonnes a year of nylon monofilament into the fishing industry. At Fishy Filaments we think it may be quite a bit more than that, and maybe all the way up to 400,000 tonnes a year as there is some crossover with agricultural nets, mosquito nets and other uses for nylon ‘mono’ as Cornish fishers call it. Very little of that material gets recycled. Most gets burned or buried after use and, according to data from researchers at Australia’s CSIRO, around 1-2% of monofilament nets get lost at sea. In water the science suggests a nylon monofilament netting takes over 6 centuries to degrade. So once lost it’s effectively there for good and represents a permanent hazard to non-target species in the phenomenon called ‘ghost netting’. But from this engineer’s point of view; disposing of this material, an engineering grade plastic that is designed for a really tough application, is a tragic waste of a resource.” Said Ian in collab interview for 3D natives.

Collaboration of Two 3DPI Awards 2021 Winners

At Fillamentum, our focus has always been on creating practical solutions that make a difference, and we were deeply impressed by the work of Fishy Filaments. So much so, that we decided to join forces with them on a joint project called Fishy Filaments by Fillamentum.

Together, we are committed to advancing sustainable practices and offering a tangible solution to the challenges posed by discarded fishing nets. By collaborating with Fishy Filaments, we are taking a proactive step towards reducing waste and mitigating the negative impact on our environment.

In 2021, a collaboration between Fishy Filaments and Fillamentum gave birth to the Fishy Filaments by Fillamentum project. What’s noteworthy is that both companies clinched the coveted 3D Printing Industry Awards in the same year. Fishy Filaments emerged victorious in the “Sustainability in Additive Manufacturing” category, while Fillamentum claimed the title of “Material Company of the Year.” Is it merely a coincidence?

Porthcurno

Porthcurno is a sustainable 3D printing filament made from recycled fishing nets with a translucent appearance resembling the sea, ideal for aesthetic and artistic 3D printing projects while also being suitable for functional models due to its mechanical and chemical resistance.

Features:

✅High temperature resistant

✅Impact resistant

✅Flexible

✅Strong

OrCA®

OrCA® is a high-performance 3D printing filament made from recycled fishing nets and 10% (original formulation, but now 17% CF is being tested) recycled carbon fiber cut strand fill, making it the most environmentally friendly option in its category. Its excellent mechanical properties make it a great choice for engineering applications, where strength and stiffness are essential.

Features:

✅100% recycled polyamide 6 + 10 % recycled carbon fibers

✅Exceptional strength and stiffness

✅Creep resistance (resistance against deformation under long-term load)

✅Low thermal expansion

Fishy filaments comparison