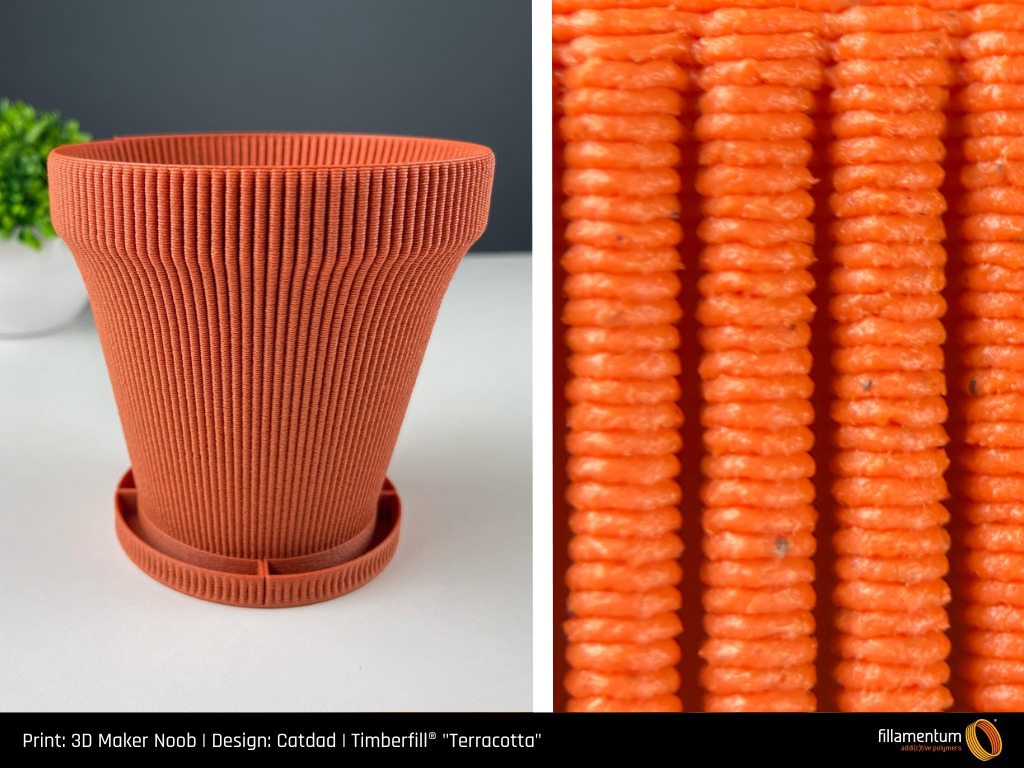

Timberfill Pots by 3D Maker Noob

3D Maker Noob, also known in the 3D printing community as Joe, is an experienced maker who has been using Timberfill®, a filament that contains real wood chops, for some time. He fell in love with this material immediately and created unique plant pots with a rustic touch.

Joe printed his first 3D model seven years ago and since then, he is fascinated with anything to do with 3D printing, which we can also see when we look at the prints he created, they are just perfect. This time Joe uses Timberfill®, a type of filament that is a combination of load-bearing material with an admixture of real wood fibers embedded inside it.

It is one of Joe’s most favorite filaments due to its unique texture and surface finish.‘’Personally, I find it to be one of my all-time favorite wood-infused filament. The texture and surface finish is something that I have only managed to achieve through Timberfill®. Not to mention that you can somewhat treat it like wood, so you can sand and stain it.’’ Moreover, you can actually see the real pieces inside and it also produces a fresh wood smell when printing.

According to Joe, one of the main differences between Timberfill® and other wood-filled filaments is the surface finish of the model. ‘’I can only assume that this is attributed to a higher concentration of wood particles in the filament. While this may restrict you from using smaller nozzle sizes, I always found it to be an advantage seeing as larger nozzles allow you to print in larger layer lines. This will always add that extra effect to the finish which personally I find makes most models look even more pretty.’’

Creating decorative items with Timberfill® is a good way to go, as the wood chops in the filament can add a unique, rustic touch to these items, making them stand out. ‘’I always felt it is the perfect material to accompany models that require that natural look of an organic finish. I have a thing for plant pots and lamps so whenever possible, Timberfill® is always my go-to material for such things. It just gives it a very unique finish.’’

3D Maker Noob has not had any problems with this material, but it still needs to be treated cautiously as you can easily wreck the nozzles. Having large particles inside means that a standard 0.4 mm nozzle would get clogged. ‘’I printed these pots by Catdad Workshop in 0.5 mm layers with an E3D Revo 0.8 mm nozzle in vase mode and they turned out gorgeous.’’

As 3D Maker Noob has a lot of experience with 3D printing we asked him for a few tips regarding working with a wood-filled filament. ‘’I always make sure I use a minimum of a 0.6 mm nozzle for Timberfill®, to completely eliminate any possible jams. Print slowly and don’t overheat the nozzle, the last thing you want to do is cook the filament. As cheesy as it may sound, treat Timberfill® with the same respect a carpenter would treat a piece of wood.’’

In addition to the material used, the printer plays a significant role in the printing process. ‘’These terracotta-inspired pots were printed on the Prusa MK3S+ which has an E3D Revo nozzle system. I used the 0.8 mm Revo nozzle and printed them at 0.50 mm layer height. The models are printed in vase mode, which is ideal as you don’t have to worry about retraction and therefore end up with a very clean print.’’

Another 3D Maker Noob’s favorite feature is that the prints can be stained as classic wood, making this filament even more natural-looking and wonderful to work with. He tested four new colors of Timberfill®: Redheart, Terracotta, Southern Pine, and Charcoal. If you want to know more about Joe and his beautiful prints, you may visit his website.

Follow 3DMakerNoob: Web, Twitter, Facebook, Twitch, Youtube, Patreon

Follow CatDad: Printables, Instagram, Twitter

USED MATERIAL

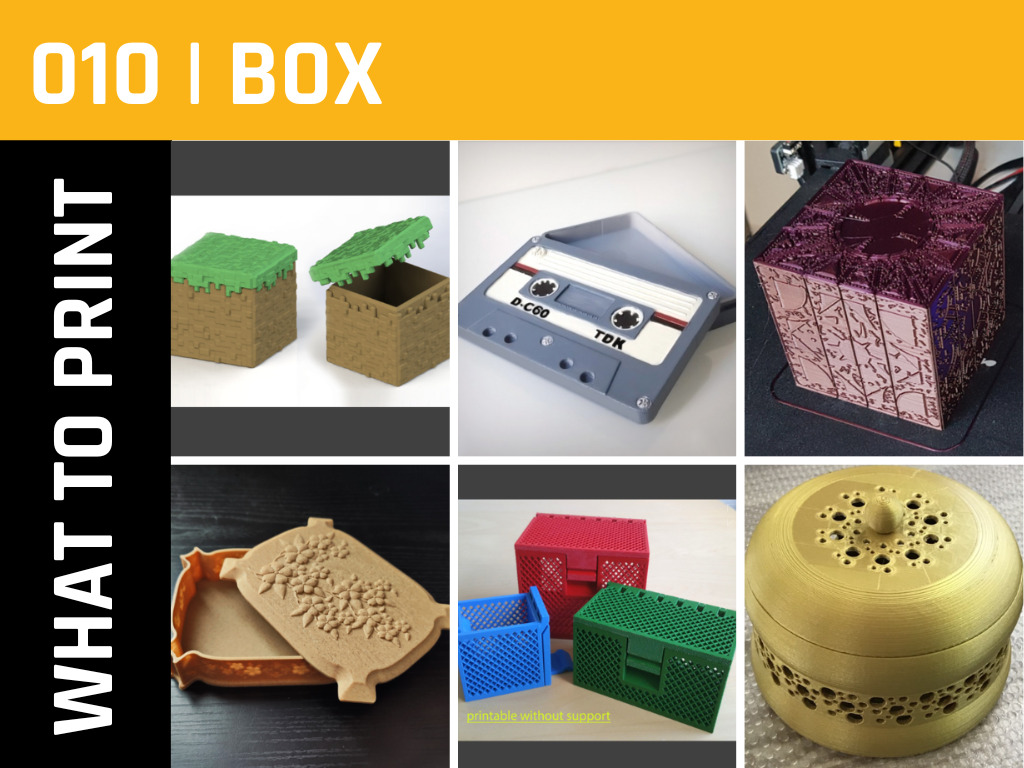

PS: If you need more ideas, check out our WTP season!