The Year 2021 in Review

The year 2021 was undoubtedly one of the more challenging years, just like 2020. That’s why we greatly appreciate the work of our colleagues and huge thanks to our customers and the whole 3D printing community. Thank you for your trust, support, and loyalty. Now, however, we must once again look optimistically to the new year 2022, in which we are planning a lot of news. But first, let’s recap the previous year.

Fillamentum is Material Company of the Year 2021

Our company, the Fillamentum brand, has received the coveted 3D Printing Industry Award in the Material Company of the Year category in October 2021. We really appreciate that the years of development of our innovative 3D printing materials have paid off and that we know that the path we have taken is the right one. Thank you for your support! Much of the credit for this, of course, goes to the material that changed the rules in the 3D printing world – NonOilen.

And what are 3DPI Awards?

Since its inception in 2016, the 3D Printing Industry Awards have become the largest additive manufacturing industry poll, with winners selected by public vote. Unsurprisingly, this year’s awards were held online due to pandemic conditions. Despite this, it received a lot of attention. “We were overwhelmed by the phenomenal response to this year’s 3D Printing Industry Awards. Nearly 140,000 votes were cast in 20 categories,” commented Michael Petch, editor-in-chief of 3D Printing Industry magazine, in an official announcement about the record turnout

Emphasis on Sustainability

Fillamentum has become a MICRO-TREND setter in sustainability. In March 2021 it launched NonOilen – the first 100% biodegradable filament for 3D printing. This product has been developed thanks to a long-term collaboration with the research team of prof. Ing. Pavel Alexy, Ph.D.from the Slovak Technical University in Bratislava. Thanks to Fillamentum NonOilen idea of “Green Prototyping” was also created, which is aimed at socially conscious customers, especially from the engineering and automotive sectors.

The biobased filament is made from a blend of polylactic acid (PLA) and polyhydroxy butyrate (PHB) to yield improved toughness and temperature-resistant properties. It can be reused time and again to adhere to the principles of a circular economy.

Once an object printed with NonOilen reaches the end of its lifecycle, it can be fully degraded to biomass, water, and carbon dioxide (CO2) in compost or food waste disposal or sent back to Fillamentum for recycling. The company has also joined the DHL GoGreen program to neutralize its carbon footprint with each NonOilen parcel sent via the delivery service.

New Innovative Solution

In addition to NonOilen, we have introduced other innovative innovations to the world:

- Flexfill PEBA 90A – Flexfill based on polyether-block-amide (PEBA), which was specially developed for processing by 3D printing

- Fluorodur – Made of polyvinylidene fluoride (PVDF) which ensures great mechanical properties and unmatched chemical resistance

- PP2320 in black color – Made of commodity plastic that offers great toughness, low moisture absorption, and electrical insulation

- 3 new PLA colors – New colors made especially for hobby customers: Peppered Mustard, Turkey Egg, and Volcanic Dust

- New ASA colors – Vetrtigo Grey, Vivid Pink, Dijon Mustard and Snow White

Where we showed up

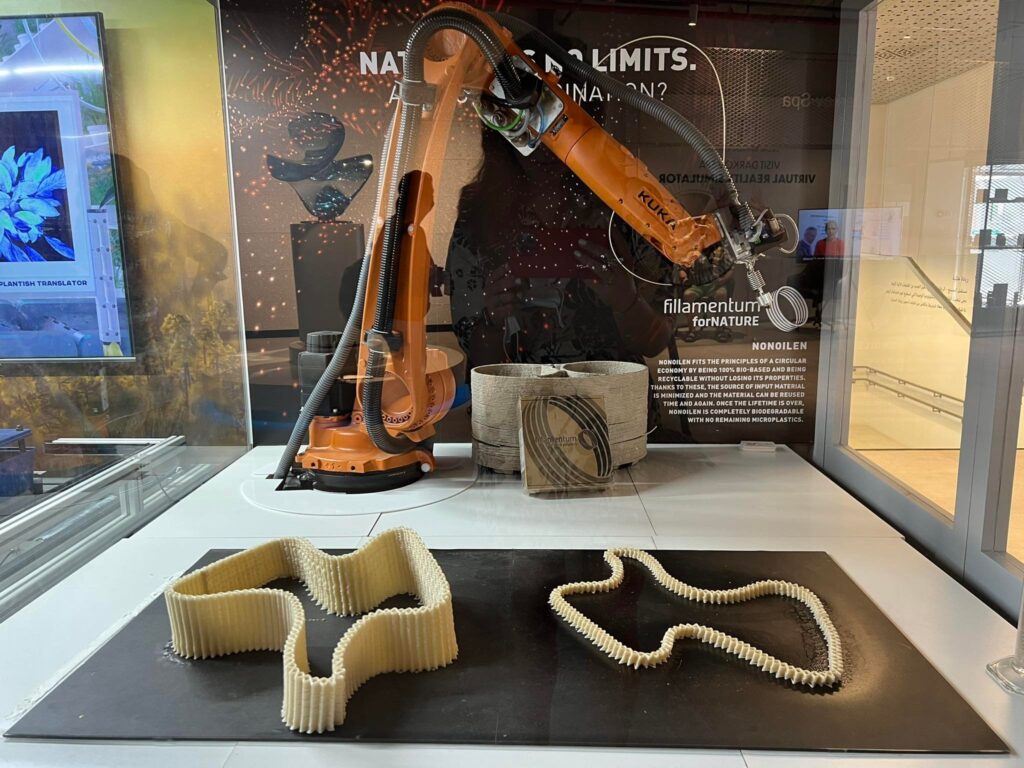

NonOilen became part of the spectacular EXPO2020 event in Dubai, where it was on display from 1 October to 31 March. The Fillamentum exposition was partly interactive. NonOilen material was printed throughout the exhibition using a robotic arm, which is being developed in collaboration with the Brno University of Technology and its spin-off company 3Deposition. Directly for EXPO2020, the NonOilen material was enriched with Dubai sand.

But you could also see us at other important events such as TCT 3Sixty, Advanced Engineering or Formnext. We are planning many more stops in 2022, including the aforementioned Advanced Engineering and Formnext. We look forward to seeing you there!

Cooperations

Just like last year, this year we also established cooperation with important scientific institutes and companies and became part of countless projects. We are rightly proud of this. It is worth mentioning, for example, the cooperation with student projects such as the Brno FabLab or the French FabLab DeVinci. We are also very happy to have been able to support projects that contribute to a better life for pets. We are talking about Pawsthesis and AnyoneGo. With our new product NonOilen, the idea of “green prototyping”, which was first encountered by Fremach, was also born. We very much appreciate the fact that we can show the rest of the world that it is also possible to manufacture sustainably.

Expansion

To accommodate our customers and partners’ needs, we have furthermore decided to increase our production capacities. One of our main priorities was the expansion of our global network of resellers and partners. Last year we also expanded our distribution network. Specifically, we expanded into the following countries:

- Singapore

- Saudi Arabia

- Greece

- Switzerland

- Iceland

- Australia

- South Korea

- UK

- USA

Looking ahead to 2022

Our ultimate goal for the upcoming year is to grow our production capacities to accommodate our partners’ and resellers’ ever-growing network. We are determined to continue to build strong partnerships, cooperations, and collaborations with organizations, professionals in the field, and educational institutions. One of our main objectives is to offer innovative solutions for manufacturers and hobby makers alike. We certainly want to continue to emphasize sustainability and continue to set trends in this area. The first step in this regard will be to switch to greener spools. We have already implemented these, but only for NonOilen filament. We, therefore, want to gradually have all our filaments wound on spools that are particularly suitable for recycling. But it’s not all about us. Every person, employee, or customer can contribute to a better environment, and we at Fillamentum will do our best to spread our message as effectively as possible. THINK GLOBALLY, ACT LOCALLY!