Fishy Filaments by Fillamenum

OrCA® – The World’s first 100% sustainable Nylon with Carbon

Published on October 25, written by Laila

We couldn’t be more excited about the arrival of Fishy Filaments in our offer. These are filaments made from recycled fishing nets – Nylon PA6. OrCA® – 100% recycled Nylon with an additive of recycled carbon fibers – was the first from this collection to appear in our offer. The industrial sustainable material of the new generation has wide applications in not only the technical sphere.

Waste to Wonder

To create this unique material, nylon PA6 is recycled from the ship’s fishing nets in the Cornwall area (UK). Fishermen from this place take their destroyed unnecessary nets for further processing and thus contribute to reducing sea waste. The following sorting and cleaning process creates a unique product that uses recycling to create new material for 3D printing needs.

What is Nylon PA6

PA6 is a type of nylon, chemically called polyamide 6. It is a frequently used type of plastic whose history dates back to 1939. This type of Nylon is used primarily in the form of fibers worldwide because the yarn made from it is about 20 times stronger than wool and elastic, which is a massive benefit for the fashion industry. However, thanks to its mechanical and chemical properties, it has also gained the status of a material with wide use in the technical sphere.

What is OrCA®

OrCA® is a compounded version of Fishy Filaments nylon reinforced with recycled carbon fibers. It’s a hi-performance nylon 3D printing filament that is a great choice not only for ecologically thinking engineers. The name was given from the shortage – A near zero carbon – O as 0, r for recycled, and CA for carbon. This nylon compound contains 10% recycled carbon fiber cut strand fill.

“PA6 has its place, but not many people found the place yet. Because they don’t start to print with so sort kind of material.” Michael Hunt, 3DprintCornwall

Features

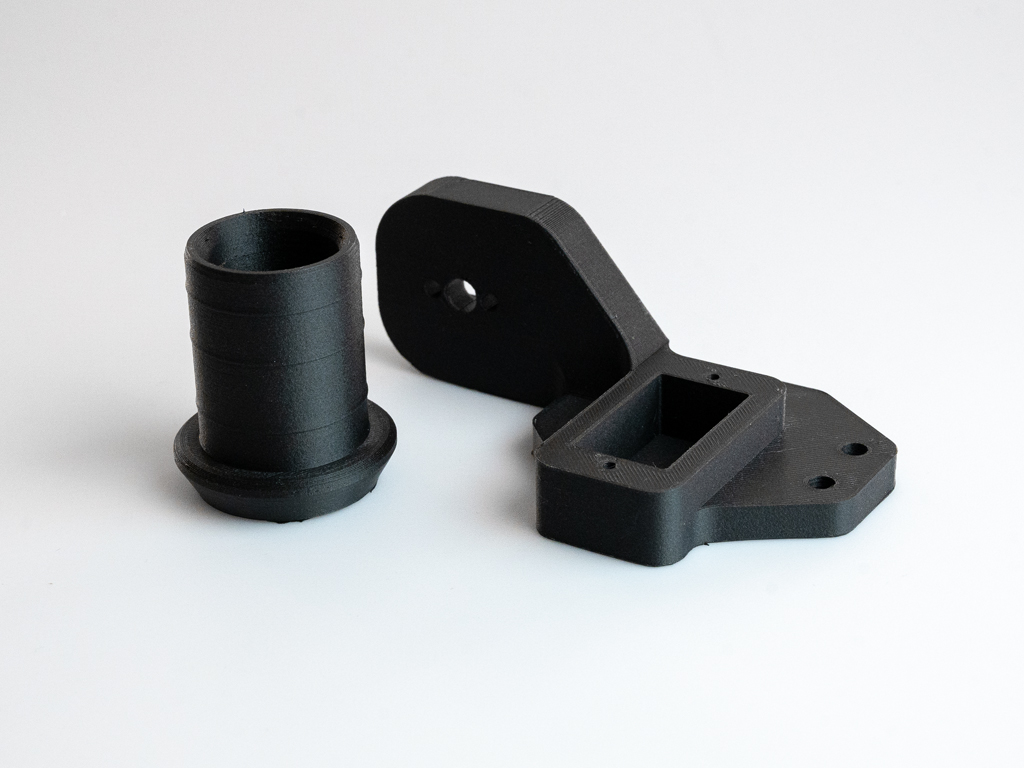

OrCA® is a technical polymer ready to be a material partner for demanding printers. Not only because of its origin but also because of its properties, it is a big competitor to products of this type in 3D printing. Absolutely unique in its composition resources.

- 100% recycled material = 90 % recycled polyamide 6 + 10 % recycled carbon fibers

- Exceptional strength and stiffness

- UV stabilized

- Wear resistance

- Creep resistance (resistance against deformation under long-term load)

- Exceptional temperature resistance up to 180 °C

- High tensile strength also at high temperatures

- High impact resistance is also preserved under low temperatures (at -20 °C)

- Low thermal expansion

- Safe to use in electrical and electronic equipment

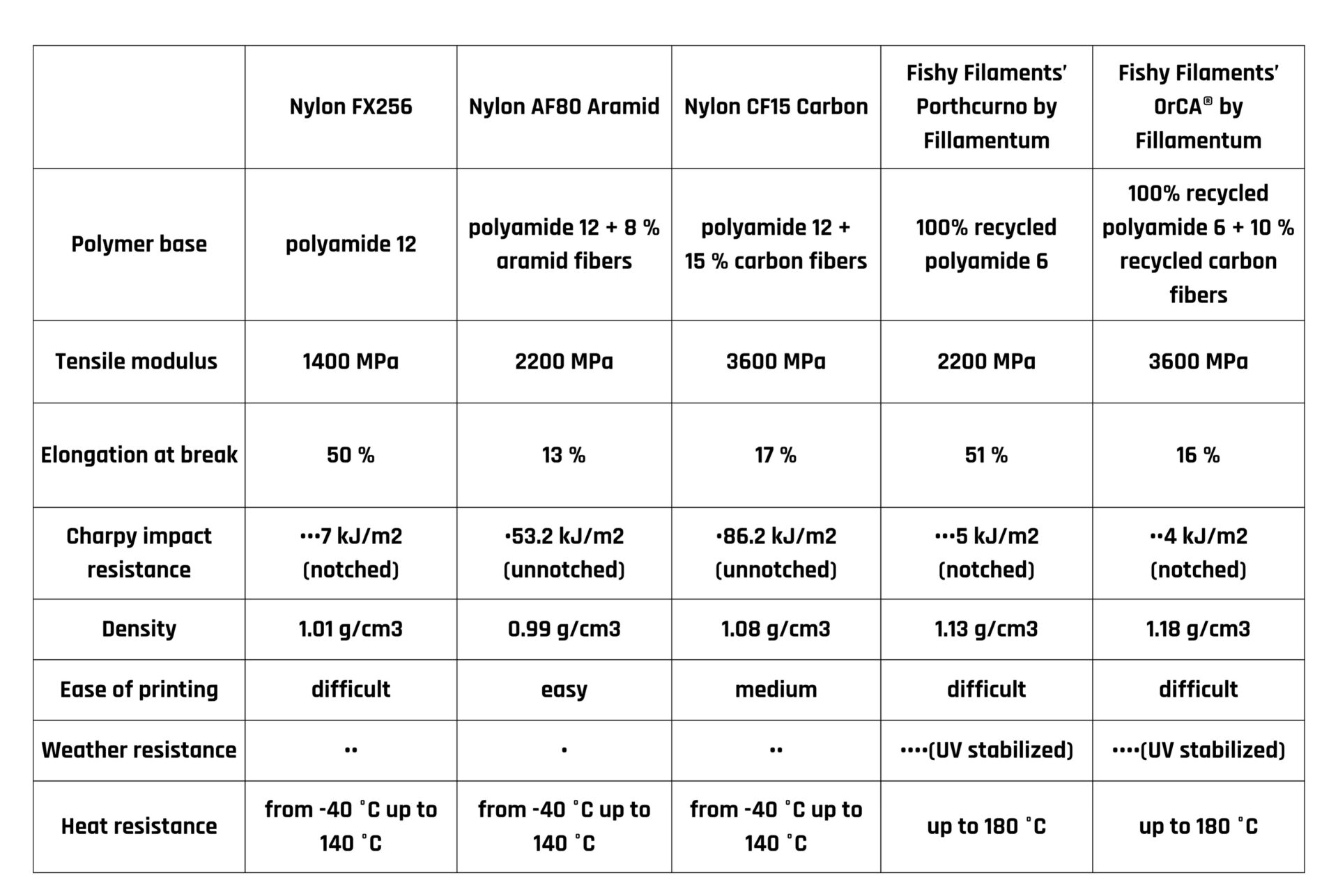

Comparison with other Nylons

Ecological impact

OrCA® is produced from 100% recycled resources. Let’s dive into the real ecological impact of this high-performance 3D printing material. More than 200,000 tons of fishing nets are produced every year. Think of it as a scale:

- 1 000 x Statue of Liberty

- 1 000 x Adult Blue Whale

- 952 x Average-sized Locomotive

- 29 000 x African elephants

From this colossal production number, only around 15% is recycled, and 1% is lost in the deep dark blue water, which takes up to 600 years to decompose. The rest of the waste, 84%, is disposed, meaning an unnecessary CO2 is produced and a massive waste of technical material that is possible to recycle.

Where others see waste, Fillamentum sees the future!

Filalmetnum has committed to doing its best to introduce the largest possible amount of sustainable materials into the world of 3D printing in its portfolio. As a material company, it adapted its operation to this. Not only does he have his own research and development team, but it cooperates with universities and scientists worldwide.

The first material in the Fillamentum ForNature line was NonOilen®, a bio-sourced material that leaves no microplastics after composting. Now comes a collaboration with Fishy Filaments and 100% recycled 3D printing filaments. And it definitely doesn’t end there.

Printing OrCA®

OrCA® is a technical 3D printing filament requiring proper technical equipment. The most crucial part is drying before printing because PA6 is highly moisture-absorbent.

Drying

Drying is the basis of printing with Fishy Filaments. You need to have sufficient drying power to process this material. We recommend you dry your spools before printing them overnight at 80°C. Temperatures below 70°C are not effective for drying.

Experiences from users:

- Sunlu – yes, for 24 hours

- Apium F300 – yes

- Oven – not recommended

- Pizza oven – not recommended

- Silica gel – not recommended

- AMS Bambu unit – not recommended

“If you don’t have a dryer, you’re always gonna fail. You can’t win. You can’t succeed.” Michael Hunt, 3DprintCornwall

Adhesion

- It is recommended to use a large brim around the printed object.

- The best results were achieved with LockPAd and Garolite.

- Glass beds must be prepared with PVA glue or Magigoo PA, not because of poor adhesion but for a powerful bond. You need a separation layer of glue for this type of bed.

- Although Nylons usually don’t stick well to PEI, small rounded parts can print on PEI.

Printing OrCA®

Enclosure – The moisture absorption of this technical material is high. We recommend delivery of the filament from a heated caddy or desiccator at 50°C to extend the printable life and increase print reliability. Full enclosure from the holder of the spool to the chamber. That means a heated chamber is recommended.

Working temperature: 250–270 °C

Heated bed: 80–110 °C

Brim – The raft is recommended for the best results and should be bigger than 10 mm.

Cooling – It’s necessary to turn off the part cooling fan. Too high part cooling fan speed or too fast cooling of the printed object can lead to warping and shrinking.

Printed parts – If it’s possible at construction, avoid sharp corners touching the build plate. It can increase the warping effect when printing nylon.

Nozzle – Minimum size is 0.6 mm. We strongly recommend using hardened or wear-resistant nozzles because, as with all other carbon-reinforced materials for 3D printing, OrCA® is abrasive. We also recommend a silicone layer on the outside of the nozzle with a silicon layer surface.

Storing

We highly recommend storing your spools in an airtight bag with desiccant. In case of moist material, re-dry it in the appropriate device. The conditions to achieve optimal moisture level are 80 °C for 5+ hours. Processing of moist filament may cause degradation of polymer chains, brittleness, poor layer adhesion, stringing, oozing, etc.

Soon - Porthcurno

Soon, we will be happy to introduce Porthcurno, another Fishy Filament that contains 100% recycled fishnets. Both the polyamide (nylon) and carbon fibers are recycled, making this the lowest carbon impact material in its class. Porthcurno filaments can be used in homewares, wearables, fashion, etc. Aesthetic-pleasing products can be printed from it due to its attractive translucent blue-green color.

Think before you print!

As with all materials, we would like to invite you with the slogan “Think before you print” to think about how you, too, can help the environment by reducing the amount of waste during 3D printing.

- Each time you print, think about whether it is really necessary.

- If the printer is well set up.

- You can reduce both material consumption and defects.

- If possible, use recycled materials.

- Give them for recycling or throw the failed pieces and waste into the properly sorted waste.