Sustainable 3D printing with Fishy Filaments

Light Pads for Playgrounds by Playerverse

Published on October 30, written by Laila

Playerverse is a growing company that is an excellent example of how community life and mutual help can bring profit to everyone. For its Light Pads – Playground Buttons, they use OrCA plastics obtained by recycling local fishing nets, 3D prints locally, and grow globally.

Hello Playerverse

We are delighted to have been able to speak with Mark Jennings, founder and director at Playerverse. He introduced us to his company: “Our goal is to become an industry leader in immersive, interactive technologies and gamified experiences. We began by creating virtual reality games with custom controllers and wearable technology, but Light Pads have proven to be very popular, so it became our first commercial product.”

The Light Pads

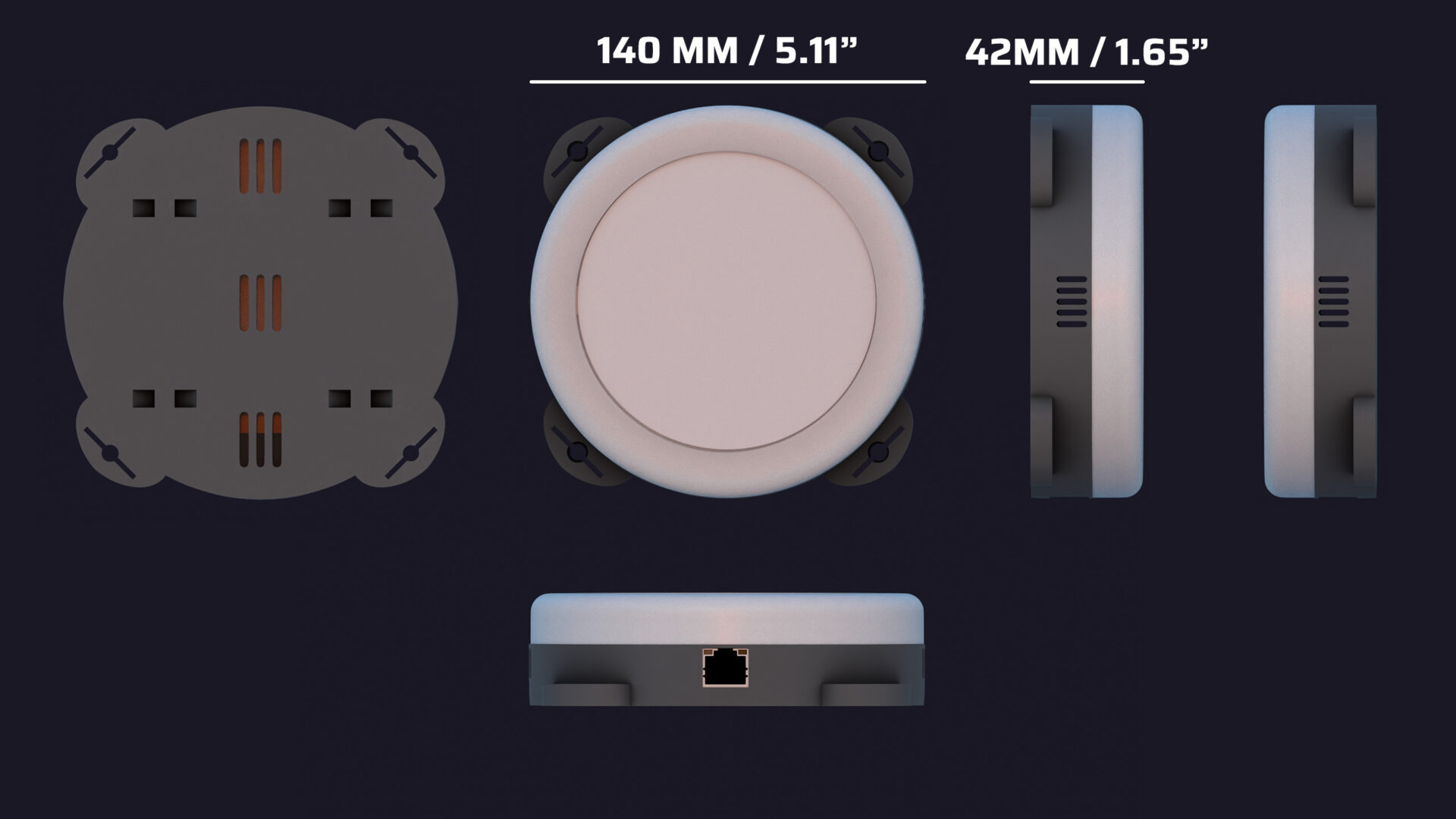

These pads are simple devices developed to be installed in children’s soft-play areas and to be a part of an interactive experience. “These are literally smashed by kids all day long hardest they can,” says Mike Hunt from 3D Printing Cornwall, the official manufacturer.

The pads are attached easily with zip-ties to netting and are quickly ready for an interactive game motivating to move around the playground. Kids have special wristbands with RFID chips for easy activating the games.

3D printing FTW

The pads consist of three main parts, two of which are 3D printed. The front PETG part, the back OrCA part, and inside the electrical device. The company started to prototype the product to get it as fast as possible with the iteration and planned to switch to injection molding right after they were ready. “However, given how tough we’ve made the product with 3D printing materials, we will probably remain with 3D printing,” Mark explains why he will stay with FFF for producing pads.

The construction

These pads look very simple, but much development was necessary to achieve this result. The first issue appears because the first prototypes were printed with PLA. The objects get soft because the central operational unit gets heated to 50°C. Mike came up with the idea to print it with OrCA Nylon, which could help not only with the heat issue but also can stand the constant hitting. “We developed the gasket to go around; there are brass insert hold everything together,” Mike explains how they deal with the impact energy that goes into the Pads.

Choosing OrCA

Mark explains why they picked up OrCA for their product: “The fact that it’s environmentally friendly is a huge bonus, and it’s great to be supporting the Cornish community, but primarily because it’s so strong! For all practical purposes, it’s indestructible. The PLA design was fairly tough and is arguably good enough to withstand a beating from children, but the OrCA nylon version is so tough I have thrown a Light Pad at a hard surface many times, and I barely even notice scratches.”

Reduced, optimized!

Choosing a more robust and durable material helped reduce the printing material from 300 g to 91 g. This provided not only material use savings but more than 5 times stronger parts as a welcomed suitable bonus to requirements for production.

Where can you find them

For equipping one playground, you need to install usually 16 to 48 Light Pads, but of course, much more can be used. “We also provide an Android touchscreen and a leaderboard display. It’s a very plug-and-play solution.” Mark explains. These days, Playerverse installs Light pads at Family Entertainment Centres but aims for a larger audience in the future. And they already think about the future: “Oh yes, we’ve got a roadmap of products for this industry that we are beginning to rolling out.”

Outro

These Pads are such great examples of how local production can be sustainable and helpful for everybody. The material for producing OrCA Nylon is made from recycled fishing nets from Cornwalls Seas. Developed and 3D printed locally, too. We wish joy for all small and big kids who will have fun with these!

Used Materials

Discover Playerverse

What can you read in the CS?

follow us

Check out more CS