THE USAGE OF INNOVATIVE MATERIALS

IN THE FOOTWEAR INDUSTRY

Flexfill PEBA: Pioneering the Future of Footwear

with 3D Printing Innovation

Published on 20 July, written by Martin O.

Meet Oldrich Voyta, the visionary Czech shoe designer revolutionizing the footwear industry with the power of 3D printing and Flexfill PEBA 90A. From personalized, comfortable shoe designs to the remarkable inaugural shoes of First Lady Eva Pavlova, explore how this cutting-edge material is redefining aesthetics and performance in shoe manufacturing. Discover the exciting possibilities of Flexfill PEBA as it sets a new standard for sustainable, stylish, and functional footwear.

Who is Oldrich Voyta?

Oldrich Voyta is a Czech shoe designer whose success has gone international. He studied for his master’s in Footwear Design at the Tomas Bata University in Zlín. He now continues his doctoral studies, focusing on the implementation into footwear. As a head of research: Zonal Personalized Footwear, he won the 1st prize in the national final of the FameLab scientific competition. He has worked as a senior designer for several years in Beijing, at VO5 studio and DeFacto design&technology studio, where alongside the team, he holds the 1stprize in the RedDott Award 2018 for a wearable high-tech mak-shaped air purifier. He regularly presents his work in the world and the Czech Republic. In the past, he has participated in Beijing Design Week, London Fashion Week, Milano Design Week, Consumer Electronic Show – CES in Las Vegas, 3D Expo in Paris, Designblok, Mercedes Benz Prague Fashion Week, etc. The themes of his work are usually inspired by the lines of the human body, which come from the biomechanics of human movement. His specialization is a combination of aesthetic design, functional style, and the use of non-modern technologies, including 3D scanning, 3D knitting, and of course 3D printing itself.

Fillamentum X Oldrich Voyta

Fillamentum established cooperation with the young designer a long time ago, in 2015, when we introduced the first flexible materials to the world – The Flexfill series. In that time, countless unique footwear design projects were created. For example, Oldrich printed the first wearable flexible footwear prototype in the Czech Republic. But the breakthrough only came with releasing a revolutionary material that is optimal for these applications. We are talking about none other than Flexfill PEBA, from which Oldrich printed the sole for a functional prototype of smart sensory footwear.

Oldrich’s work with NonOilen® is also worth mentioning. It is this material that created the PARADE collection, which perfectly combines art, sophisticated design, sustainability, and 3D printing. It was a great success that the collection was presented in Paris at the Palais Chaillot National Dance Theatre, moreover, now this footwear can also be seen in the Czech Republic, specifically in the Permanent Collection of UMPRUM Museum in Brno.

First Lady's Inauguration Shoes

In March 2023, the inauguration of the new Czech President, Petr Pavel, was marked by a remarkable fashion statement. Czech Republic First Lady Eva Pavlova stole the spotlight with her elegant custom-made shoes, designed by none other than Oldrich Voyta, which allowed her to stand out at the prestigious event.

The innovative use of cutting-edge materials in their construction made these shoes genuinely exceptional. The entire heel was expertly 3D printed by the renowned Czech company Fillamentum, using our PLA Crystal Clear. The design of the heel was cleverly inspired by the clean lines and arches of Prague Castle’s Vladislav Hall architecture, giving the shoes a touch of historical grandeur.

However, the bottom of the heel required specific mechanical properties to ensure maximum comfort and functionality for the First Lady. To achieve this, Flexfill PEBA was employed which offered the ideal combination of features, including shock absorption and slip resistance on various surfaces, making it the perfect choice.

Oldrich Voyta, the talented designer behind this exceptional creation, expressed his excitement about the success of his design. The shoes showcased his artistic vision but also demonstrated the potential of using innovative and high-performance materials in the fashion industry.

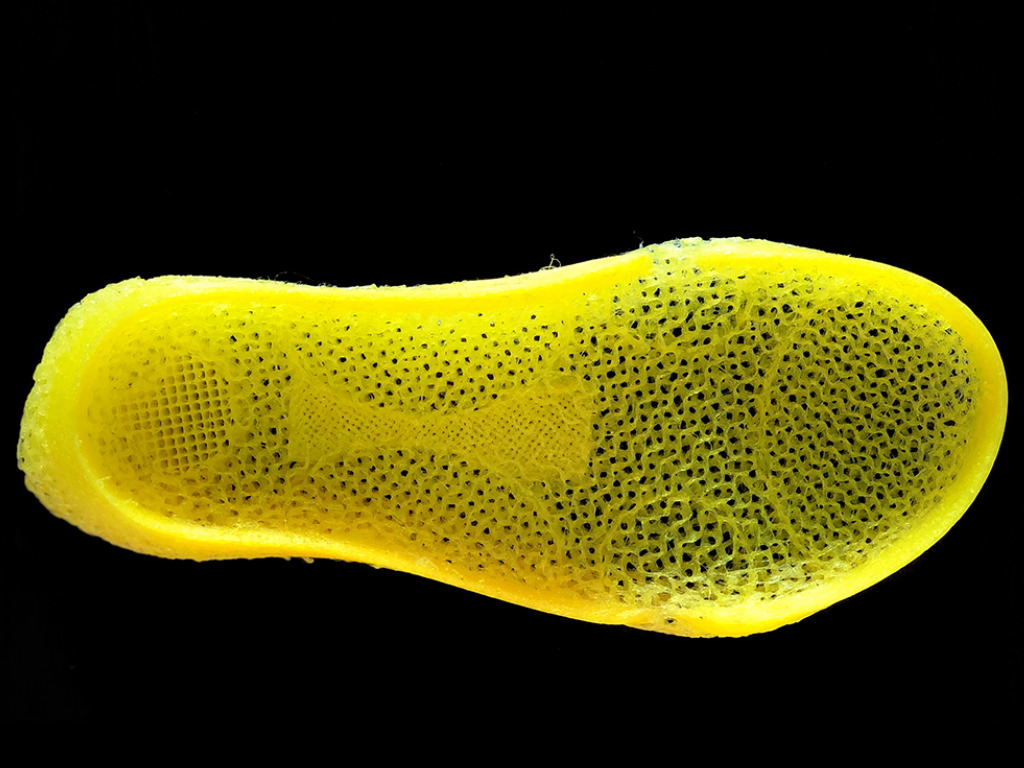

Flexfill PEBA 90A - The best material for printing soles

As you have already learned, Oldrich uses modern and environmental technologies for his design. His work focuses mainly on “tailor-made” shoes, i.e. personalized solutions that result in a comfortable and safe walking experience. “All the custom-made shoes I produce start with 3D scanning as standard. Thanks to this technology, I can create a shoe-last that directly contours to the customer’s foot. Based on this, I am then able to model the optimum sole and then use 3D knitting to make the shoe fits perfectly,” Oldrich says of his daily routine, adding, “After all, I was able to test my work on myself. I made one pair of shoes that made use of this integral method. I printed the sole with Flexfill PEBA 90A and I have to say that the material is second to none in this respect. I made the sneakers about a year ago, especially for the Karlovy Vary Film Festival. I must say that even after a year, when I wear the shoes now and then, they are still in perfect condition. Except for minor scuffs, the shoes are still 100% functional and meet all the requirements for comfortable wearing.” You can now see these unique sneakers in the picture below.

However, it is not only custom production that the young designer is currently engaged in. Flexfill PEBA also plays an important role in his doctoral studies at UTB Zlín. He is currently working on research that focuses, among other things, on optimal materials that can be used for shoes (especially soles) made using 3D printing. The research is still ongoing; therefore, the results will be published in Oldrich’s research paper. However, we did get a few words from Oldrich himself about the results: “Working with my research team represented around 900 hours of testing. During this time, we tested various 3D printing materials, especially elastomers. This cyclical testing included testing various mechanical properties, especially slip resistance, abrasion resistance, material relaxation (energy return), and membrane mechanism, i.e. shock wave containment. Although the complete results will only be published in academic research papers, I can say one thing. PEBA passed these tests with flying colors, and there is currently no material that can match it for this application“.

Oldrich has also joined forces with Bennon, a prominent the Czech shoe company known for crafting high-quality work and leisure footwear. Together, they are at the forefront of developing cutting-edge footwear using modern 3D printing technology. In this collaborative endeavor, the remarkable Flexfill PEBA 90A material once again takes center stage as a functional prototyping. With Bennon’s expertise in functional footwear and Oldrich’s mastery of 3D printing and personalized solutions, their partnership holds the promise of reshaping the industry. As they continue to push the boundaries of what is possible, the future of footwear looks increasingly exciting and tailored to meet the diverse needs of individuals in both work and leisure settings.

3D Printing PEBA vs. Injection Molding: Revolutionizing Shoe Production!

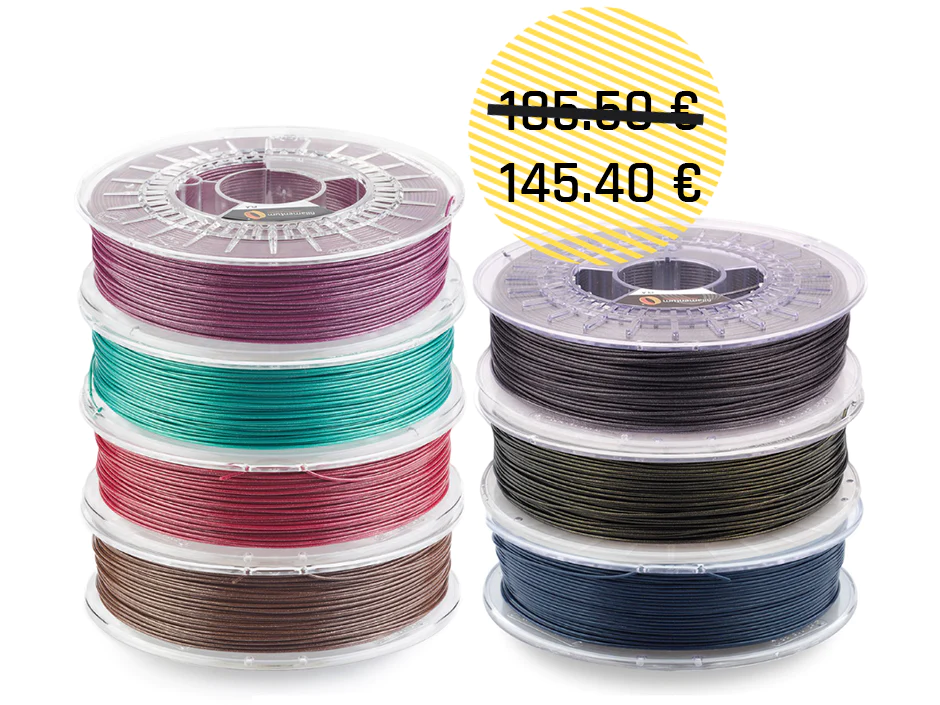

An additional point of interest lies in the comparison between 3D printing using Flexfill PEBA 90A and the traditional injection molding process with PEBAX materials. While injection molding has been a popular method for mass production, 3D printing with PEBA offers a compelling alternative for small-scale production and prototyping.

Initially, one might perceive the cost of a 500-gram filament of Flexfill PEBA 90A for 3D printing as relatively higher. However, when compared to the expenses associated with injection molding for small production quantities, the 3D printing approach becomes significantly more cost-effective. This makes it an attractive solution for designers like Oldrich who focus on personalized and limited-run shoe manufacturing.

One remarkable aspect to note is that there are no discernible differences between the 3D printed version of PEBA and the one created through injection molding. This further emphasizes the viability and quality of 3D-printed PEBA materials for shoe production.

By utilizing 3D printing technology and PEBA materials, designers can achieve the same level of excellence and performance found in traditional injection-molded shoe soles. Embracing this innovative combination opens up new possibilities for small-scale, custom footwear production without compromising on quality or functionality. As technology continues to advance, it is clear that the future of shoe manufacturing is taking bold steps toward personalized and sustainable solutions.

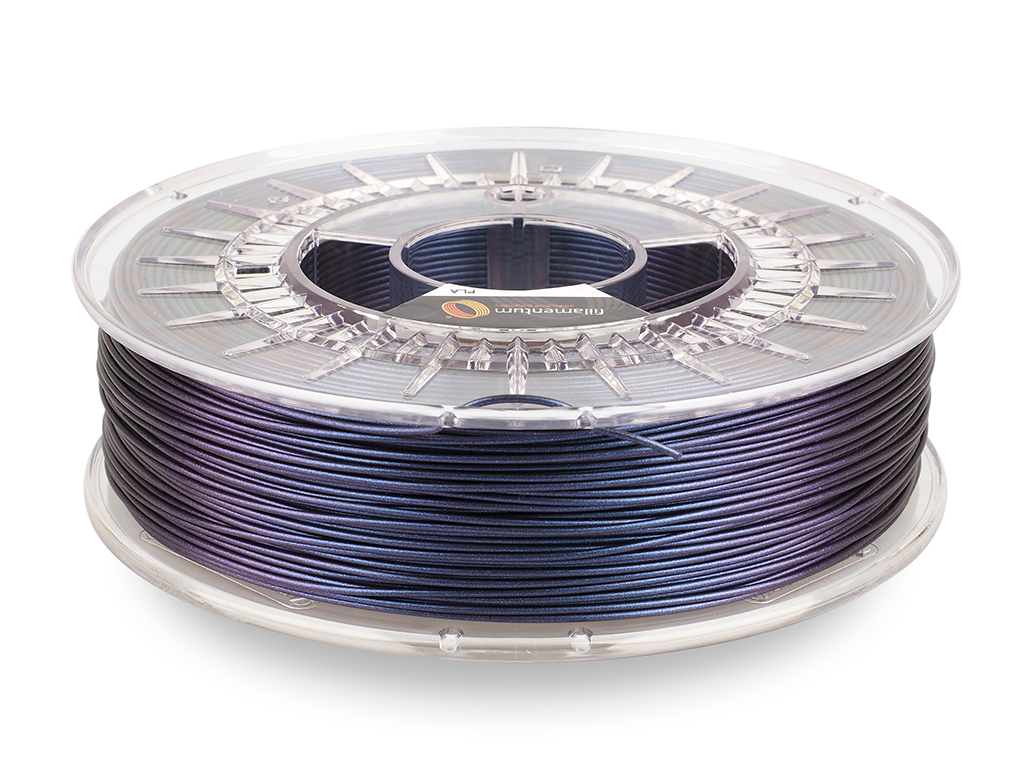

Flexfill PEBA's New Color Variations Redefine 3D Printing Aesthetics

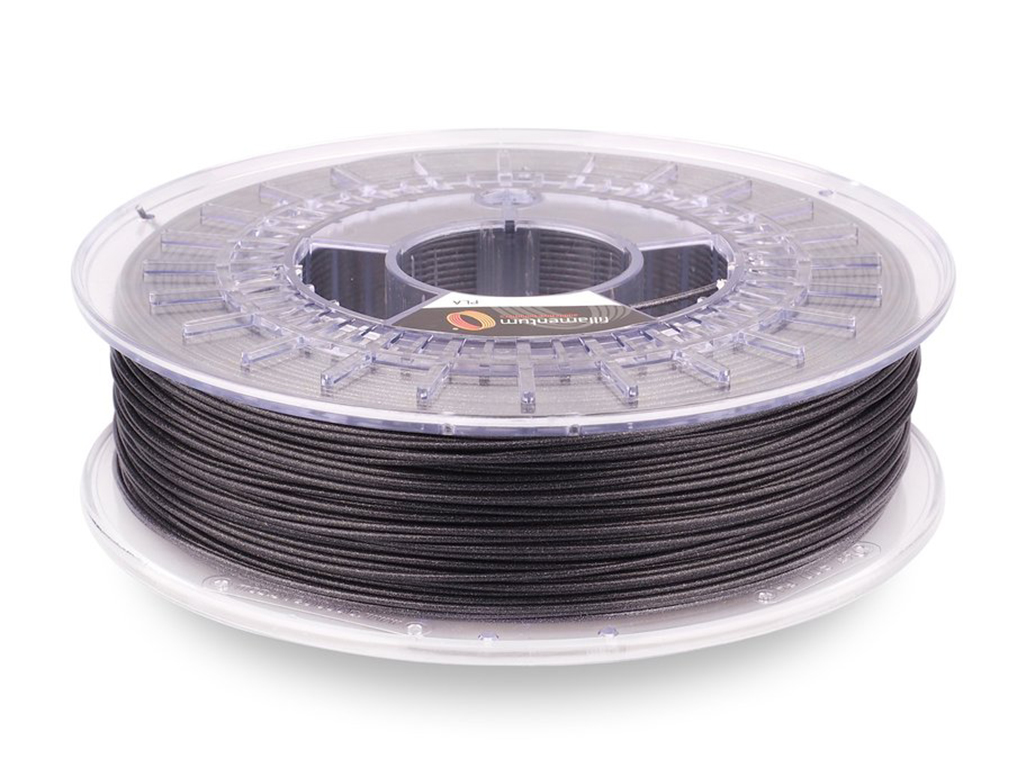

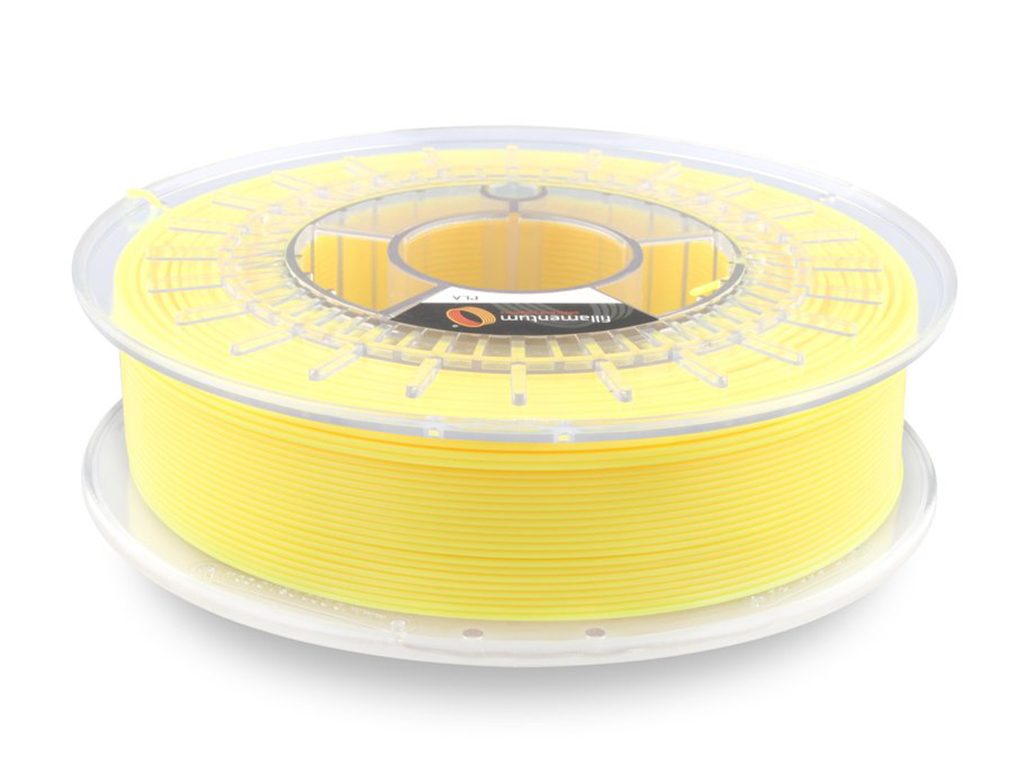

Until July 2023, Oldrich has only been able to use Flexfill PEBA in the basic natural color. However, that has changed with the new 4 colors – “Red Transparent”, “Black Transparent”, “Blue Transparent” and “Yellow Transparent”. Thanks to the new color variations, an aesthetic result can be achieved without having to color the print in post-processing.

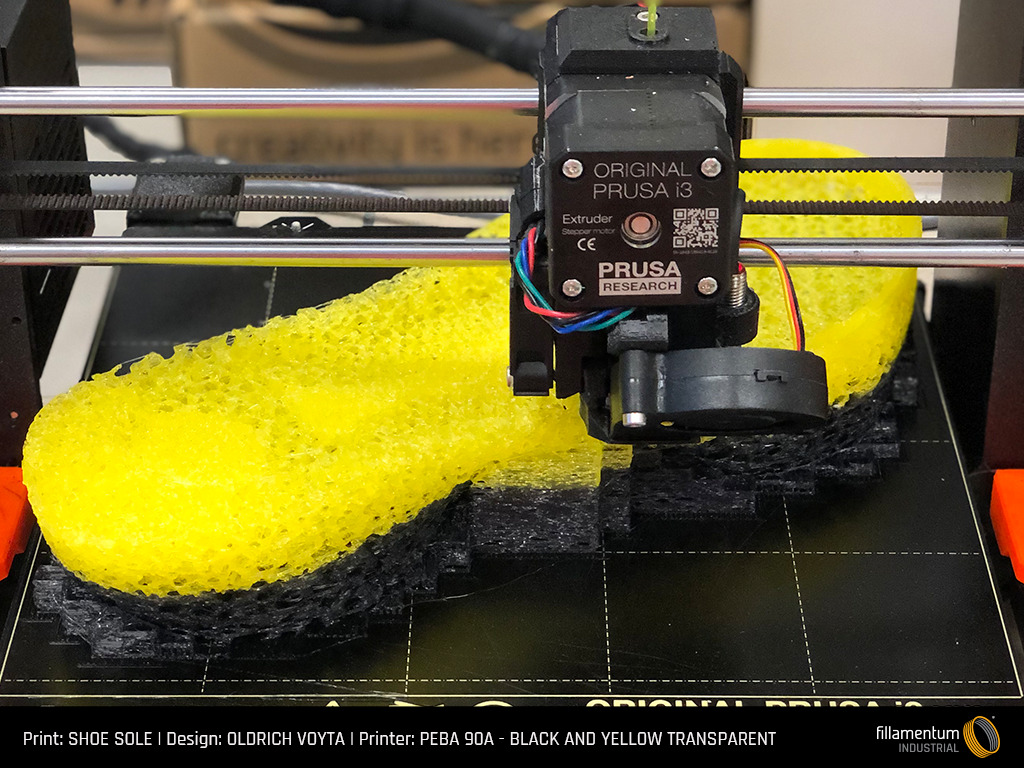

Oldrich was among the first to experience the novel color options and promptly put them to the test in his innovative custom-made shoe designs. With an artistic vision in mind, he opted for a captivating combination of “Yellow Transparent” and “Black Transparent” filaments for his two-color printing project.

And what was his reaction? “I have to say that I am delighted to see this excellent material in new colors. The colors have no effect at all on the print itself and print just as easily as the previous natural versions. It was not even a problem to print the model in two colors and there was no delamination of the layers. In short, the Flexfill PEBA prints seamlessly, eliminating unnecessary messiness, even with new colors.”

In closing, we extend our heartfelt gratitude to Oldrich for his invaluable testing and feedback on Flexfill PEBA’s new color variations. His enthusiasm and positive experience underscore the transformative potential of these innovative filaments in the world of 3D printing. We applaud Oldrich’s creativity and vision in his custom-made shoe designs, which have served as a testament to the exceptional quality and ease of use of Flexfill PEBA’s latest offerings.

As we venture into this new chapter of 3D printing possibilities, we eagerly anticipate witnessing more extraordinary projects and inspiring creations from Oldrich and countless other enthusiasts alike. With Flexfill PEBA’s remarkable advancements in aesthetics and performance, the future of 3D printing holds boundless promise and excitement.

Follow Oldrich Voyta

What can you read in the CS?

follow us

Check out more NEWS

SPAM

The best choice for versatile printing