Fillamentum Celebrates

10 years!

Celebrate with us as Fillamentum marks an incredible 10 years of innovation, creativity, and passion for 3D printing. We thank you for your support and look forward to another decade of new possibilities. Join the celebration!

OUR JOURNEY

Josef Doleček | The Founder

“I’ve always believed that innovation and technology have the power to make the world a better place. When I first encountered 3D printing, I knew that this was the direction I wanted to pursue. I wanted to create something that would not only help people build and create but would also be of the highest quality, reliable, and accessible.”

Josef was driven by a passion for innovation and a desire to create products that would inspire creativity in the 3D printing community. He focused on developing specialized filaments that not only performed exceptionally well but also met the diverse needs of both hobbyists and professionals.

The first signs of Fillamentum date back to 2013 when Josef Doleček began laying the groundwork for a company dedicated to high-quality 3D printing filaments. Fillamentum was officially established on April 12, 2014.

The early days were filled with extensive experimentation and collaboration with customers to refine product offerings. Josef’s experience in the plastics industry proved invaluable, as he applied his technical knowledge to ensure that Fillamentum’s materials were of the highest quality and consistency.

As the company began to grow, it quickly gained recognition in the market, establishing a reputation for excellence that set it apart from competitors. The official launch of Fillamentum signified not only the birth of a company but also the start of a new chapter in the 3D printing landscape, fueled by Josef’s unwavering commitment to quality and innovation.

“Starting Fillamentum was a dream come true for me. I wanted to produce filaments that not only performed well but also inspired users to push the boundaries of their creativity,” Josef shared.

The first signs of Fillamentum can be traced back to 2013, but the company was officially established on April 12, 2014. In its early days, Fillamentum focused on providing a wide variety of PLA filament colors and was among the first companies to implement the RAL color system. This allowed users to choose from an extensive range of colors with precision, enhancing both professional and creative projects.

Josef Doleček shared, “The inception of Fillamentum was about more than just creating filaments; it was about establishing a brand that stood for quality and creativity in the 3D printing space.”

With a commitment to innovation, Fillamentum began developing specialized materials that would cater to the diverse needs of 3D printing enthusiasts and professionals alike.

In 2015, Fillamentum solidified its presence in the 3D printing market, building on its vibrant palette of PLA filaments. The company expanded its product line to include innovative materials such as Timberfill, a wood-based filament that enabled users to create realistic wooden textures. Notably, it was through the collaboration with Akemake that the first 3D-printed wooden speaker, Spirulida, was brought to life, showcasing the potential of Timberfill in functional designs.

Additionally, Fillamentum introduced PLA Crystal Clear, known for its transparency, and TPU 98, a flexible filament ideal for durable parts.

Josef noted, “2015 was a pivotal year for Fillamentum, transforming our startup into a recognized industry player.” The company also prioritized quality assurance, ensuring that each product met high standards of performance and reliability.

Engaging with the community was a key focus, as Fillamentum participated in industry events, fostering a culture of collaboration and innovation within the 3D printing landscape.

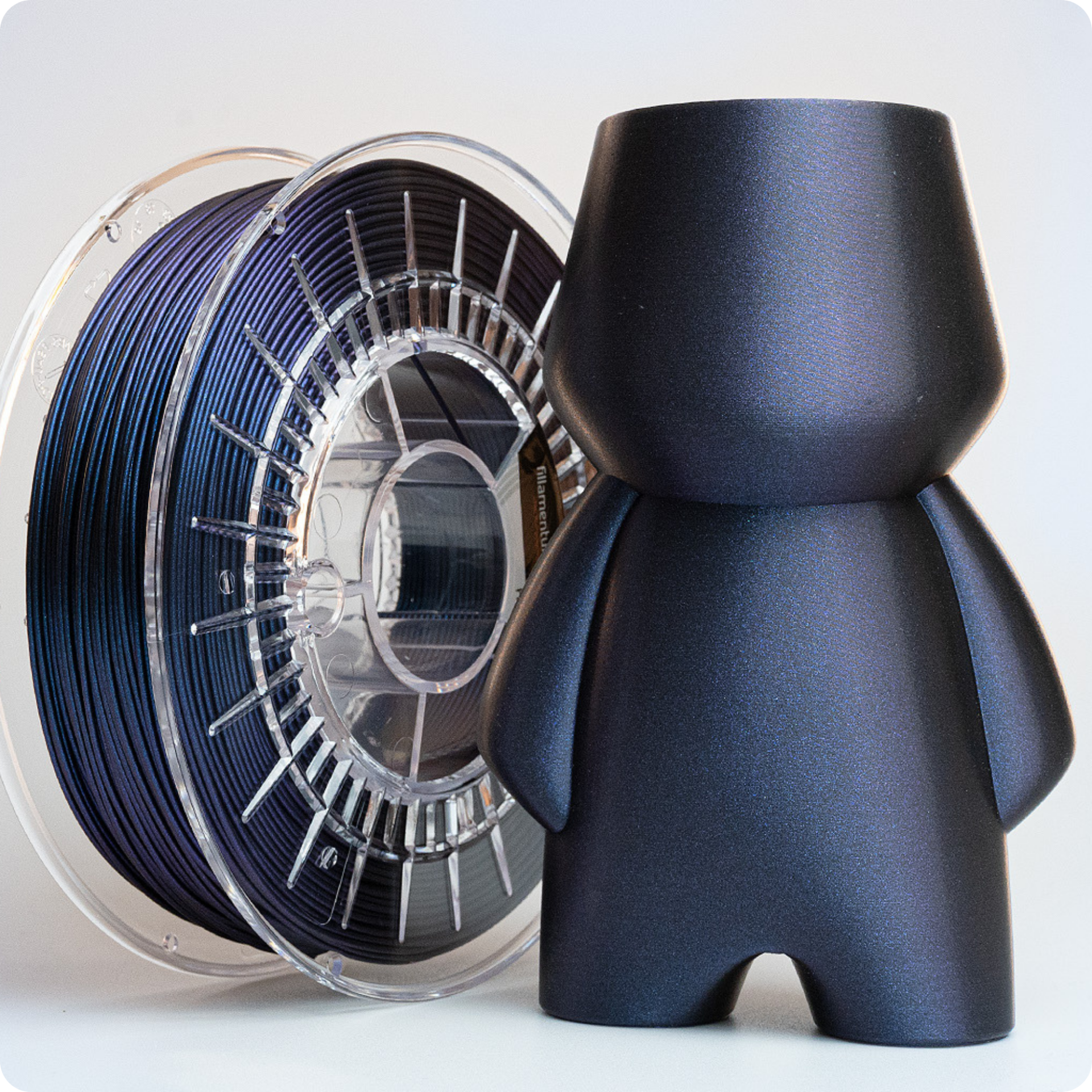

In 2017, we launched Vertigo Grey, marking a revolutionary moment in the 3D printing landscape as one of the first glitter PLA filaments. This innovative material not only introduced a dazzling visual element to printed objects but also offered a practical advantage: it effectively concealed layer lines, enhancing the overall aesthetic of 3D prints.

Josef remarked, “With Vertigo Grey, we aimed to push the boundaries of what was possible in 3D printing. It was more than just a filament; it was a new way to express creativity.” The success of Vertigo Grey sparked the development of the entire Vertigo series, which has since expanded to include seven vibrant colors, each celebrating the shimmering quality that captivated the 3D printing community. As we continue to innovate, the Vertigo series remains a testament to our commitment to creativity and quality in 3D printing materials.

In 2018, Fillamentum marked a pivotal year with the launch of the Fillamentum INDUSTRIAL line. This cutting-edge range of filaments was specifically engineered for industrial applications, addressing the increasing demand for high-performance materials in the 3D printing sector.

Josef stated, “The INDUSTRIAL line represents our commitment to developing materials that can endure rigorous conditions while delivering exceptional results. We listened to the market and crafted solutions that truly elevate industrial 3D printing.”

In a testament to its growth and success, in 2018 Fillamentum was honored as the winner of the Export Price DHL UniCredit in the Global Exporter category. This award highlighted the company’s commitment to international markets and its role as a leading exporter in the field of 3D printing materials.

The introduction of the INDUSTRIAL series not only broadened Fillamentum’s portfolio but also established the company as a leader in the 3D printing landscape, setting the stage for continued innovation and future successes.

In 2019, we proudly introduced Wizard’s Voodoo, an innovative filament that quickly captured the imagination of the 3D printing community. This filament stands out not only for its striking aesthetic but also for its exceptional printing performance, making it a favorite among creators and designers alike. Wizard’s Voodoo was designed to unleash creativity, allowing users to explore new realms of artistry in their 3D projects.

Josef remarked on this breakthrough, saying, “With Wizard’s Voodoo, we aimed to create a filament that inspires and enables our users to bring their wildest ideas to life. It’s not just about printing; it’s about the magic of creation.”

The introduction of Wizard’s Voodoo marked a significant milestone in our commitment to innovative materials, further solidifying Fillamentum’s position as a leader in the 3D printing industry.

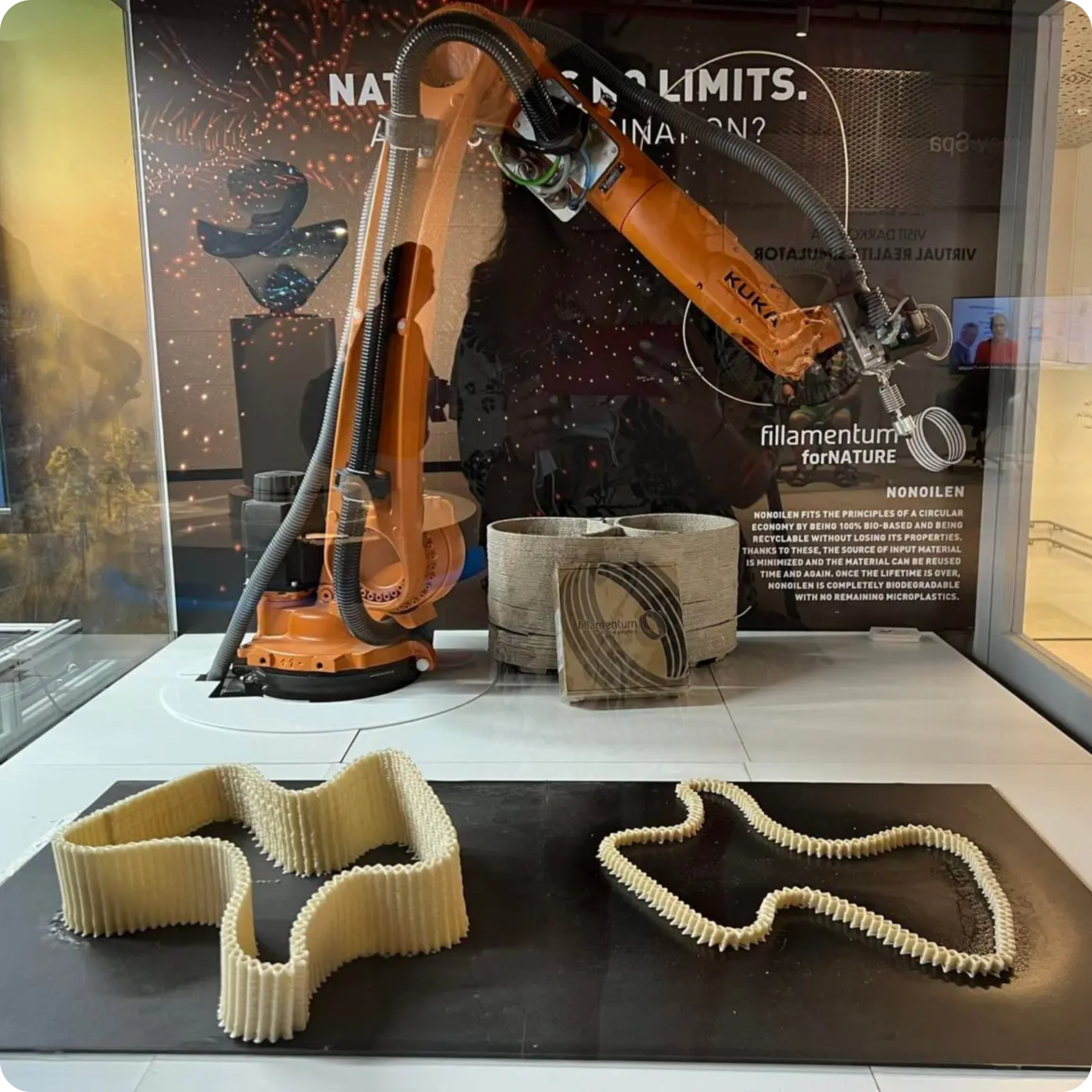

2021 marked a pivotal year for Fillamentum, as we introduced NonOilen, a groundbreaking biodegradable and recyclable filament that perfectly embodies our commitment to sustainability. This innovative material, made from renewable resources, offers a durable and eco-friendly alternative without compromising on quality or performance, positioning NonOilen as a beacon of our drive for environmental responsibility.

Alongside this major launch, we were honored to receive the prestigious 3D Printing Industry Award in “Material of the Year 2021” category, further solidifying our status as a global leader in 3D printing. This recognition from the industry and our peers acknowledged our relentless pursuit of innovation and excellence.

Furthermore, our participation in EXPO2020 was a highlight of the year. We proudly showcased NonOilen, capturing the attention of global audiences and winning the Commissioner General’s Award for the Most Sustainable Contribution. This recognition underscored our commitment to pushing the boundaries of sustainable manufacturing solutions.

Josef encapsulated the spirit of 2021, stating, “NonOilen is a testament to what we stand for—innovation with purpose. Our focus is not just on the next material, but on creating solutions that benefit both people and the planet.”

In 2023, we proudly introduced Fishy Filaments by Fillamentum, a Nylon PA6 filament made from recycled fishing nets. This initiative not only contributes to ocean cleanup but also reduces CO2 emissions and eliminates waste by repurposing a technical material that would otherwise be buried or incinerated. As Josef emphasized, “Sustainability is not just a trend; it’s a responsibility we hold as innovators in the industry.”

“As I look to the future, I see a world where technology and sustainability go hand in hand. Fillamentum will continue to innovate, pushing the limits of what’s possible in 3D printing, while keeping a strong focus on responsible production and environmental stewardship. The journey has just begun, and I’m excited for what’s ahead.”

Josef Doleček | The Founder

CATCH THEM ALL CONTEST

🎉 Join our exciting “Catch Them All” contest! 🎉

Want a chance to win 100 kg of Fillamentum filaments? Celebrate our anniversary with us and take part in this special contest!

How to enter? 🤔

- Purchase a Fillamentum product in the new anniversary box.

- Collect all six different anniversary stickers included in the boxes (stickers may or may not be in each box).

- If you find a golden sticker, you’re automatically entered into the final draw!

- Complete the form

Important! 📝

Once you’ve collected all six stickers or found the golden sticker, simply fill out the form and upload a photo of your collected stickers directly to the form!

Announcement date 📅

The winner will be announced on April 11, 2025, during Fillamentum’s 11th birthday celebration!

Get creative with our filaments, sign up now, and don’t miss your chance to win big! 💪🎨

Explore all 6+1 unique stickers

WHAT IS NEW?

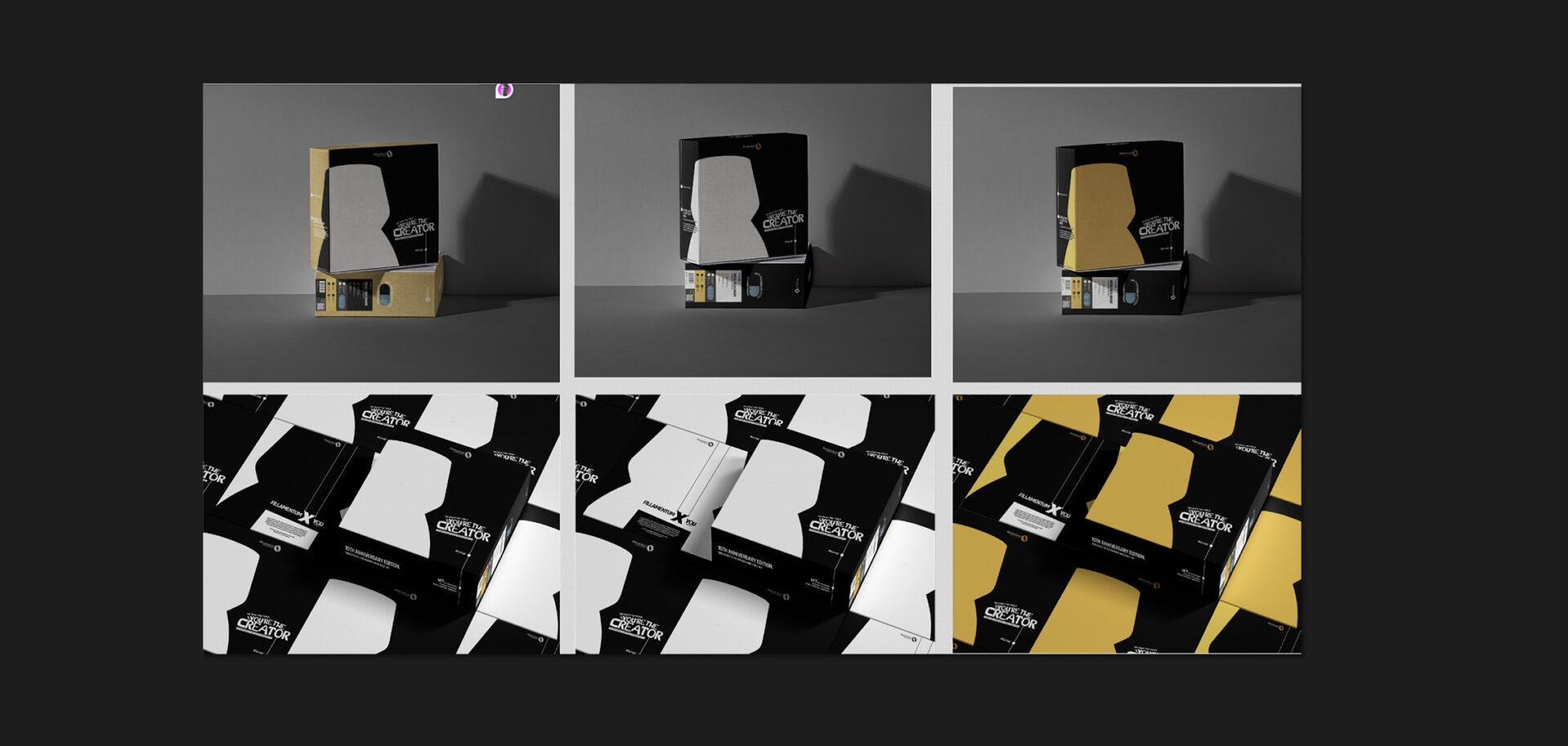

To celebrate our 10th anniversary, we’ve created something special for you – a brand-new packaging design that honors you, the creators, without whom our journey wouldn’t be possible. Our new packaging reflects not only the quality of our materials but also our dedication to creativity, simplicity, and originality – values that are essential for 3D printing. The centerpiece of this design is our mascot, Filla Fella, designed by the talented Augustin “Flowalistik” Arayo, who has become a symbol of our creative journey.

Behind the New Packaging

As Karel Kunz, Brand Manager of Fillamentum, explains, the process started as a small change to mark our anniversary, but it soon turned into a major transformation:

Phase 1:“It all began when we were celebrating our 10th anniversary. Initially, we intended to make only a small adjustment, but as you can see, it resulted in an entirely new look. Thanks to active communication with our customers, we learned how they perceive Fillamentum, and we wanted to reflect that feedback in our new packaging.”

Phase 2:“Our goal was to create packaging that tells a story – a story that connects us with you, the creators, who merge 3D printing with creativity to build something remarkable. That’s why we started calling you ‘creators,’ which perfectly aligns with our mascot, Filla Fella, who carries the message: ‘Here we are, with a white canvas ready for your creativity!’”

A Special Edition

The final package is a limited edition designed as a thank you to all the creators who have been part of our innovative journey.

Fillamentum has always been, and will continue to be, for creators who demand only the best tools. From the very beginning, we have been dedicated to research and innovation, striving to deliver an immersive and seamless experience that empowers you to create with freedom.

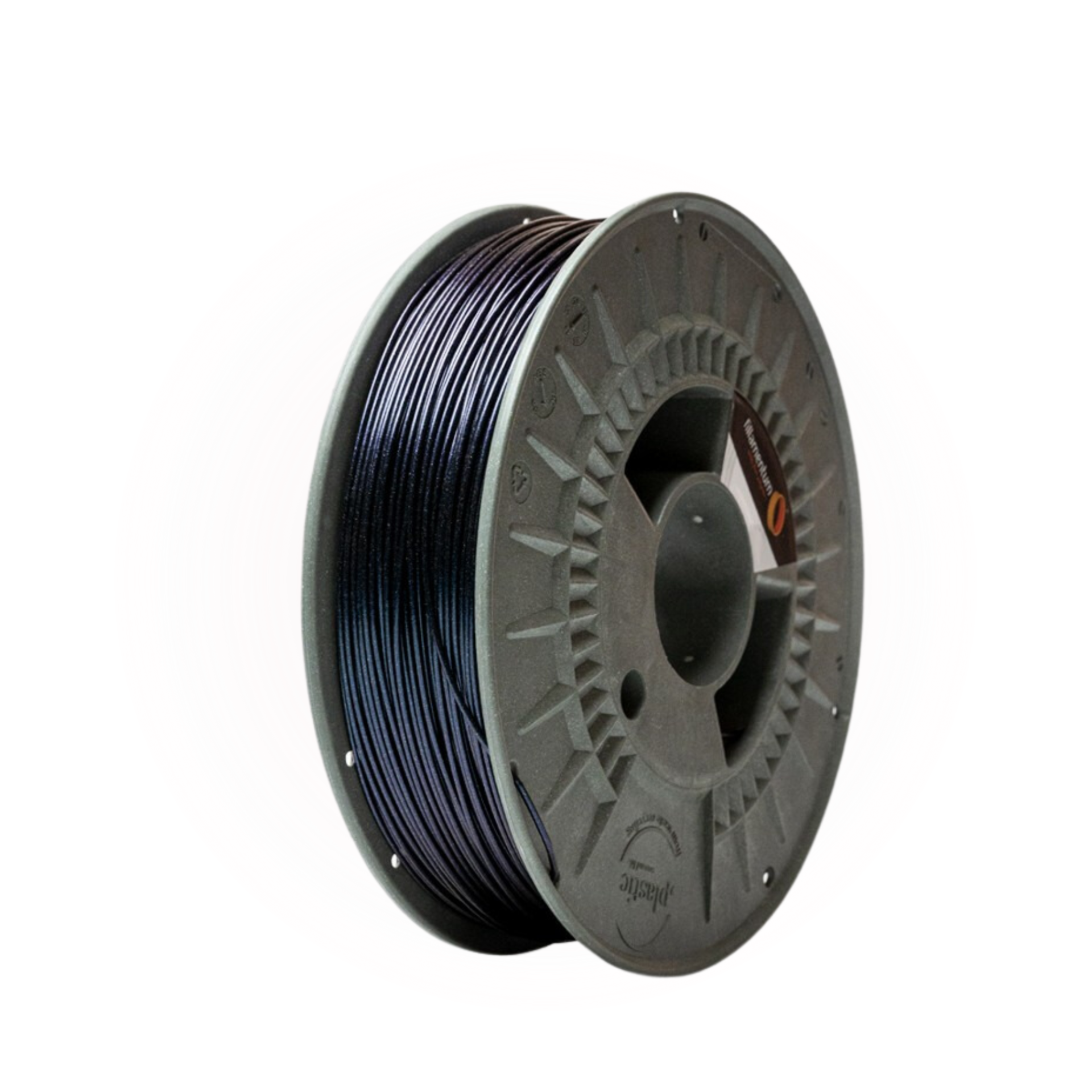

We are excited to announce that most of our materials will now be available on sustainable grey polypropylene spools, similar to those that many of you may already know from our NonOilen or PETG product line. These eco-friendly spools are designed with sustainability in mind and are compatible with AMS systems.

As the demand for sustainability and recycling continues to grow, we are committed to reducing plastic waste in our packaging. Our new spools are made with 70% recycled plastic, which aligns with our goal of promoting a circular economy. The grey color of the spools is a result of mixing recycled materials, making them easily recognizable in recycling processes.

10 YEARS OF TOP QUALITY

As we celebrate our 10th anniversary, we want to highlight our unwavering commitment to quality. While others may focus solely on diameter claims, Fillamentum prioritizes CPK (Process Capability Index) to ensure that every spool of filament meets the highest standards. Our CPK process capability consistently exceeds 1.67, guaranteeing a quality level of just 1 ppm (one defective part per million). This rigorous approach means you can confidently rely on our filaments for your projects, knowing they are among the best in the industry.