NonOilen Usage

NonOilen Powers Sterilization Solutions in Cultivated Meat

Published on September 30, Written by Gabriela V.

A medical autoclave is a device designed for sterilization under high pressure and temperature. Usually, it’s containers, instruments or liquids in laboratory glassware which are sterilized. Thanks to this device, Tomáš Keller, his team and the company Bene Meat can grow cultivated meat in the laboratory using stem cells. What is the role of 3D printing and what role does NonOilen play in this process? You can read this and much more in the new case study.

BMT changes established conventions

Bene Meat (BMT) wants to change the future of meat – meat without the need to kill animals, without destroying the planet, meat that is healthy and available to everyone at a reasonable cost. BMT develops technology for the production of an alternative protein in the form of cultivated meat, without the use of raw materials from killed animals.

“In the first phase, thanks to 3D printing, it was determined whether the path chosen by the BMT company was the right one. And because 3D printing has been currently the fastest and cheapest process, the unavailable components were printed on a 3D printer,” Tomáš Keller introduces us to the issue.

Importance of having NonOilen

Components printed from NonOilen are part of the sterilization process, carried out by moist warm air and increased pressure, which tends to be stable. All living organisms are killed, there is also coagulation of proteins, caramelization of sugars and other thermal changes of substances. It is standard to use steam at a temperature of 121°C for about 20 minutes during the process. This is the reason why the components are printed from NonOilen – its high temperature resistance is necessary. At the same time, its huge advantage is easy printing, similar to PLA. Components from NonOilen were used repeatedly in the sterilization process.

“The printing properties are the same as PLA, good adhesion in the Z-axis and little shrinkage. NonOilen is a bit stringy, but we fine-tuned this deficiency with setting up temperature,” Tomáš Keller describes his experience with printing with NonOilen.

The option to print parts on a printer is always a time and financial saving. Another no less important advantage is the possibility of modifying and adjusting individual parts with each subsequent print.

Follow The Soho Lighting Company:

What is NonOilen?

follow us

Check out more CS

SPAM

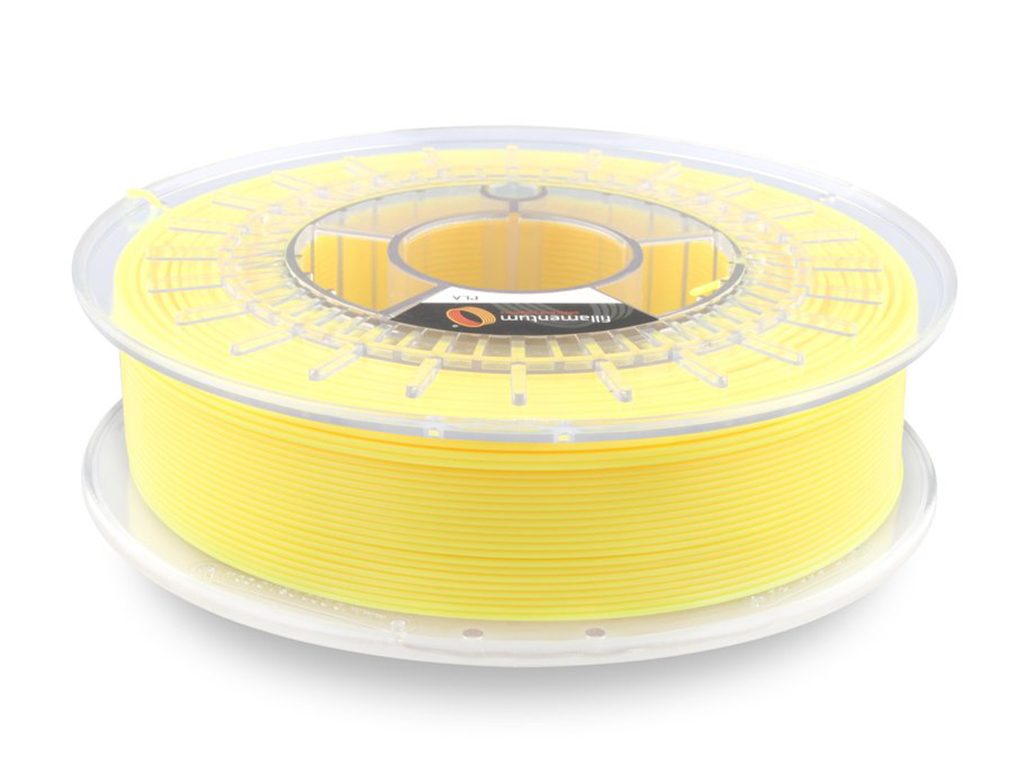

The best choice for versatile printing