USAGE OF NONOILEN IN COMPANY CNC KONEČNÝ

The Company, Engaged in the Manufacturing of CNC Machines, Has Embraced Sustainable 3D Printing and Integrated It into Their Production Process.

Published on 9 March by Martin O.

Making prototypes, speeding up the production while saving the costs and the environment. These are the crucial themes of every innovative company. One of them is the family company CNC – Konečný, that decided to streamline its production by implementing 3D printing into the production process of CNC routers, plotters and milling machines using NonOilen filament by Fillamentum.

Enhancing Efficiency and Sustainability

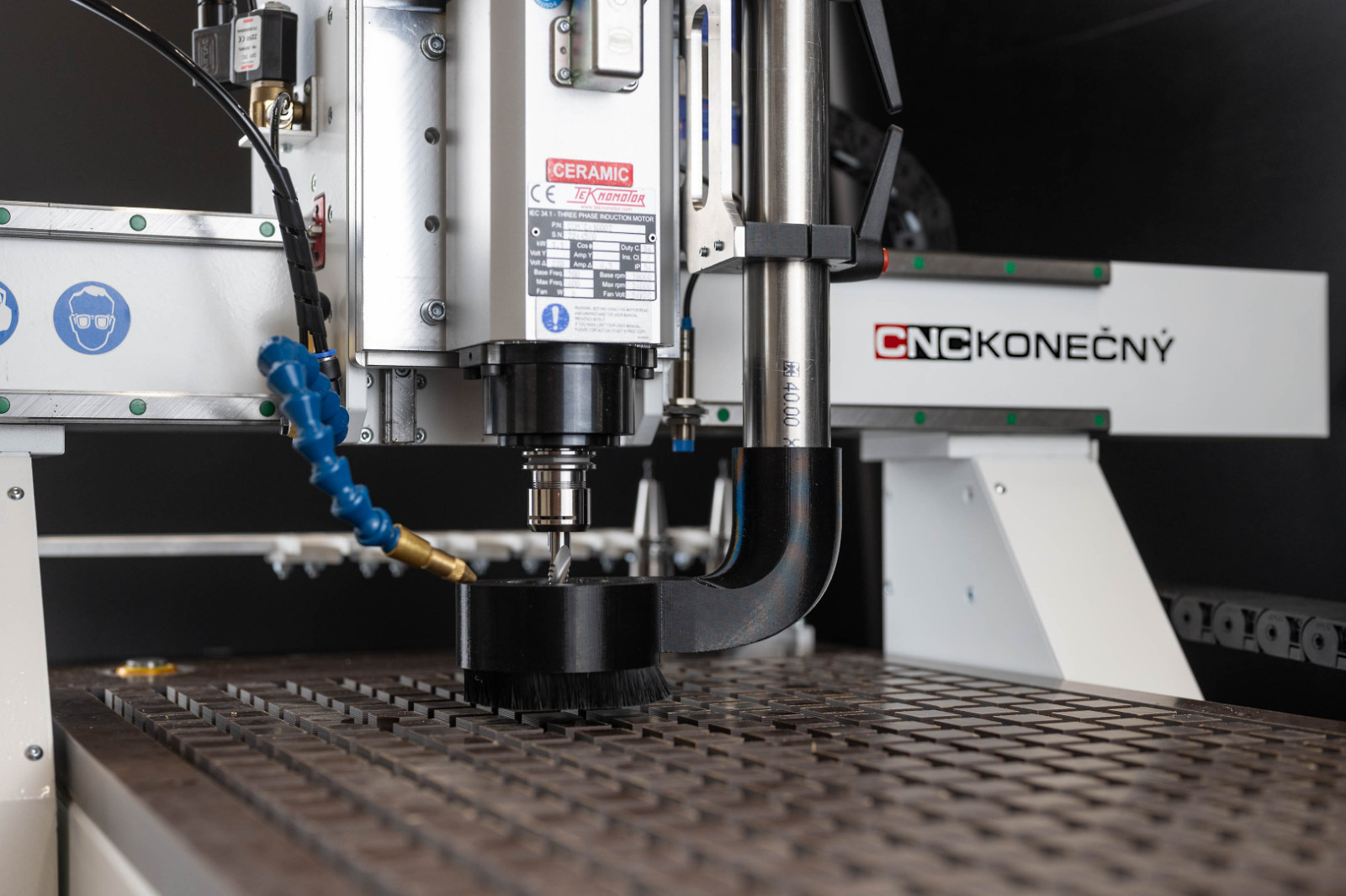

CNC – Konečný produces CNC machines from the ground up in its production hall in Boršice. Thanks to 3D printing, the development of its products is more efficient, and the company produces more optimally shaped, lighter, and sufficiently load-bearing components at the same time.

“Thanks to Fillamentum materials, our company is able to create prototypes quickly and cheaply. In addition, by implementing 100% biodegradable material, we support the circular economy, which we do not see as a mere trend,” explains Martin Konečný, the owner of the company.

3D Printing for Suction Heads in CNC Routers

Nowadays, the company is mainly focused on 3D printing of suction heads. In this case, the designers implemented into the manufactured CNC routers a cyclone extraction of chips, which requires a spatially organic shape of the head. The result is a robust, yet light component. “A nice bonus when implementing 3D printing in this case is the better efficiency of chip extraction”, highlights Jakub Říha, a developer at CNC-Konečný, another specific advantage of 3D printing in production.

Experience of 3D printing with NonOilen

And how was 3D printing with NonOilen? “Printing is comparable to PLA material. The only difference is the need to use 3DLac, because without it the print comes off the pad”, concludes Jakub Říha.

What is NonOilen?

What can you read in the CS?

follow us

Check out more CS

SPAM

The best choice for versatile printing